In 2021

Koti 15th Anniversary

FUJI FURNITURE is responsible for making and using

In 2021

FUJI FURNITURE is responsible for making and using

Koti” has become one of FUJI FURNITURE’s iconic chairs.

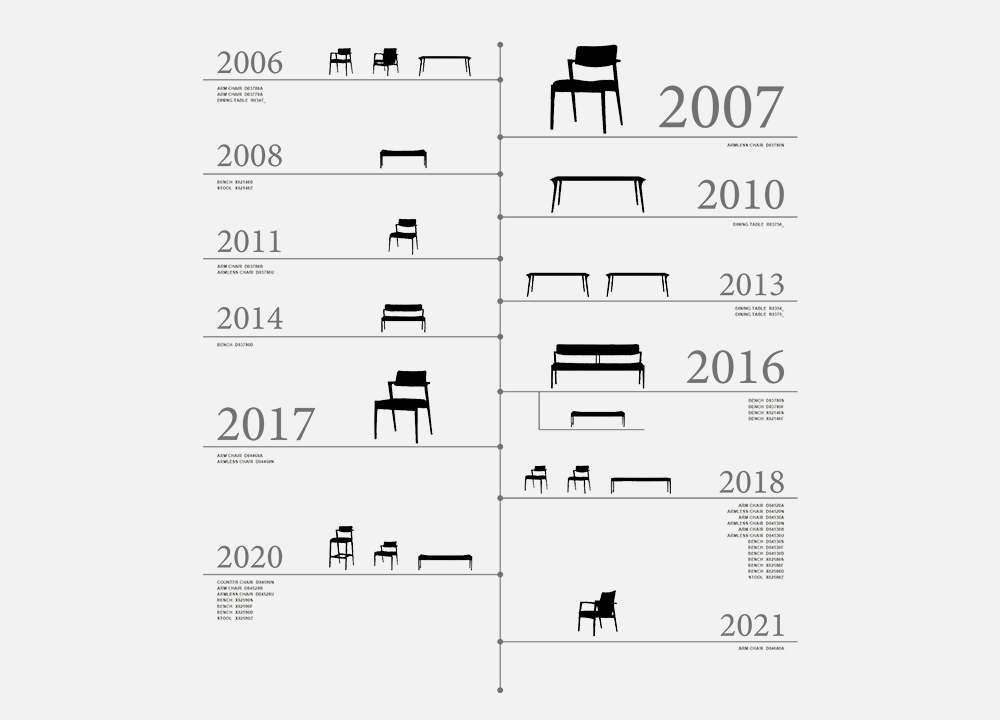

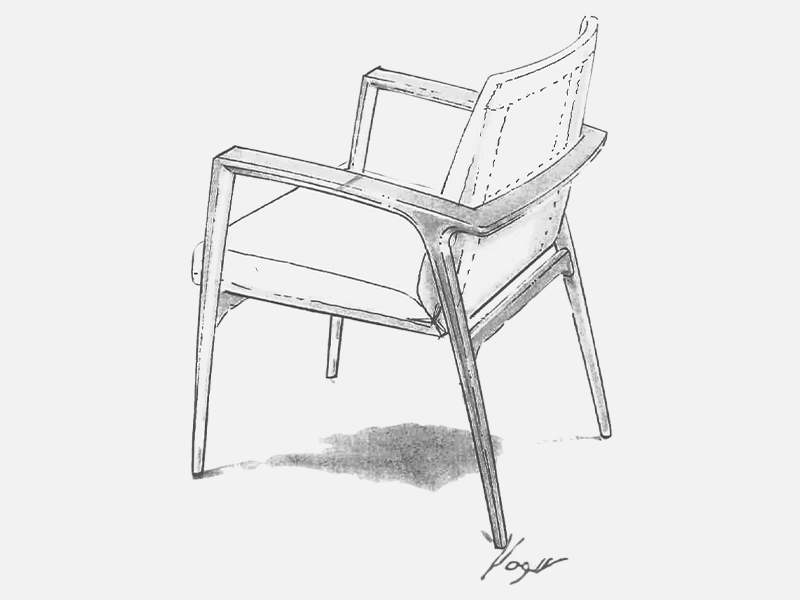

Koti was born in 2006 as a result of a collaboration between furniture designer Kazushi Suzuki and FUJI FURNITURE.

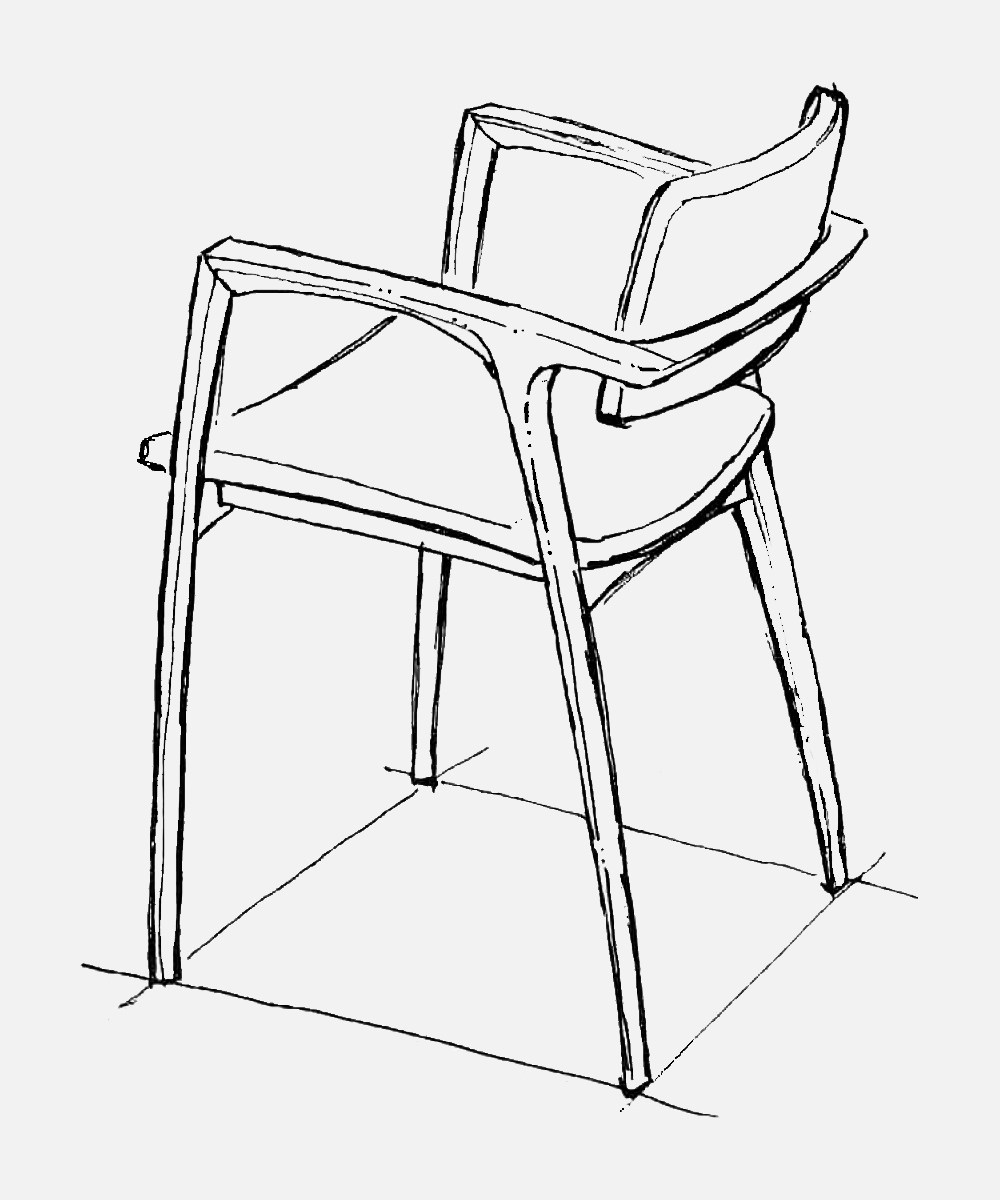

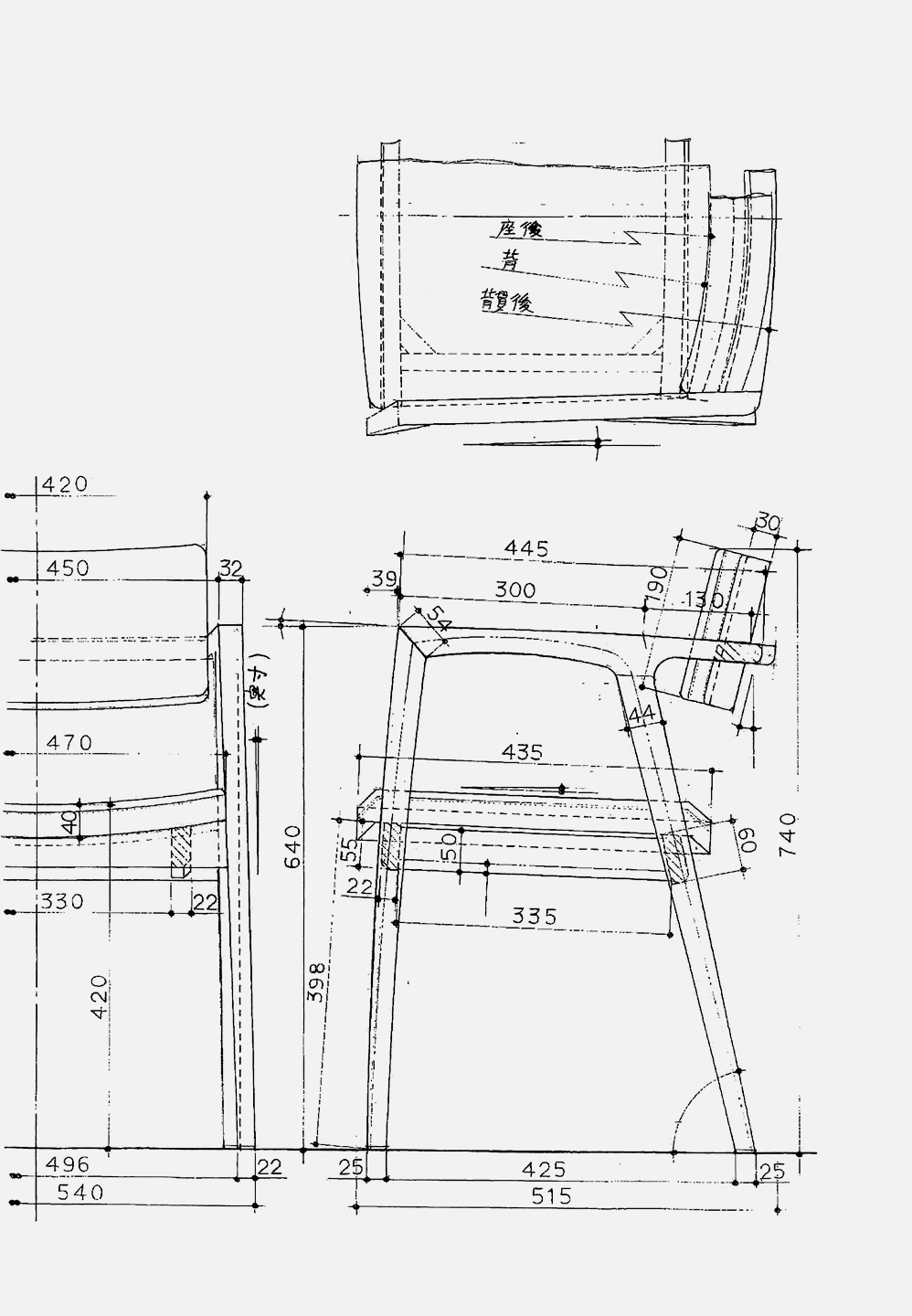

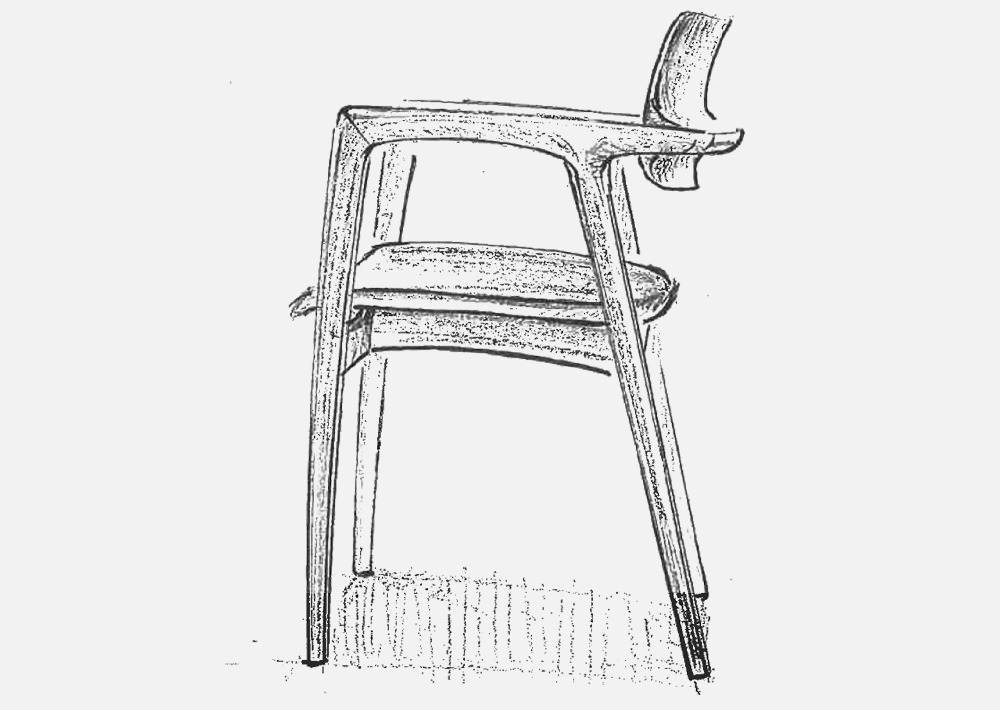

Koti is a marriage of tense straight lines and reassuring curves. Practicality in the form of cues and semi-arms. The depth of the flexible lineup. These charms attract us at first sight, seamlessly connect with our lives, and nurture our attachment to them.

In 2021, Koti celebrates its 15th anniversary with a total of 55,000 units sold, a figure that will continue to grow as long as FUJI FURNITURE’s aspirations are in tune with our evolving lifestyles. This number will continue to grow as long as FUJI FURNITURE’s vision keeps pace with evolving lifestyles.

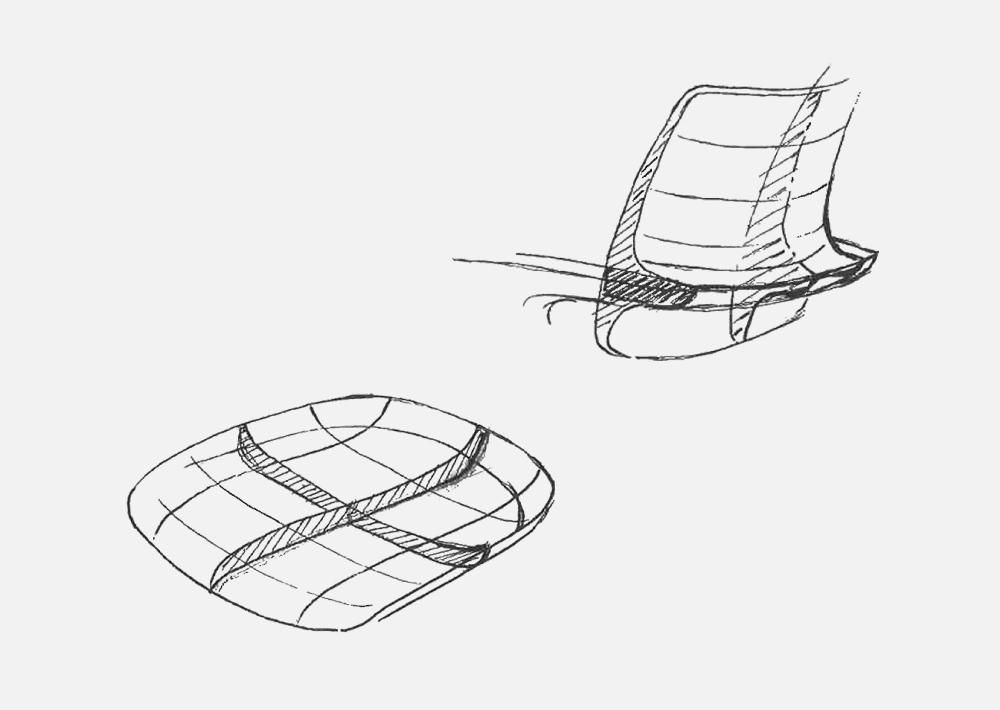

Koti started with eight items: armchair, LD chair, dining table, sofa, living table, TV board, sideboard, and cupboard. Initially, Kazushi Suzuki suggested that Koti could be made from molded plywood, but after considering that the exquisite lines of Koti could only be achieved by carving solid wood instead of molded plywood, they came up with the current specifications.

Although FUJI FURNITURE’s mainstream furniture has been made of molded plywood, this is not the first attempt to carve solid wood furniture. These chairs were made of beech wood, and Koti was made of beech wood as well.

For a while, Koti was not popular, and FUJI FURNITURE was troubled. The armless chair was born from a hint from a customer who asked if there was an armless chair. By not completely eliminating the elbow frame, but leaving it in place, we were able to combine the comfort of an armchair with the practicality of an armless chair. Since the launch of this armless chair, Koti has been in demand by many customers.

In 2007, FUJI FURNITURE began using walnut wood again, and the combination of walnut wood and black leather allowed Koti to blend into contemporary living spaces. The Koti LD chair, an armchair with a reclining function, won the Good Design Award in the same year. Koti has since become one of FUJI FURNITURE’s most popular chairs.

Koti started with eight items: armchair, LD chair, dining table, sofa, living table, TV board, sideboard, and cupboard. Initially, Kazushi Suzuki suggested that Koti could be made from molded plywood, but after considering that the exquisite lines of Koti could only be achieved by carving solid wood instead of molded plywood, they came up with the current specifications.

Although FUJI FURNITURE’s mainstream furniture has been made of molded plywood, this is not the first attempt to carve solid wood furniture. These chairs were made of beech wood, and Koti was made of beech wood as well.

For a while, Koti was not popular, and FUJI FURNITURE was troubled. The armless chair was born from a hint from a customer who asked if there was an armless chair. By not completely eliminating the elbow frame, but leaving it in place, we were able to combine the comfort of an armchair with the practicality of an armless chair. Since the launch of this armless chair, Koti has been in demand by many customers.

In 2007, FUJI FURNITURE began using walnut wood again, and the combination of walnut wood and black leather allowed Koti to blend into contemporary living spaces. The Koti LD chair, an armchair with a reclining function, won the Good Design Award in the same year. Koti has since become one of FUJI FURNITURE’s most popular chairs.

More than ever, the world has come to expect the warmth of wood and the comfort of natural materials in its furniture and lifestyle. Until then, dining tables were made of veneered wood, but in 2010, solid wood tables with horizontal joints were introduced. The expression of the wood from the grain and knots is truly one-of-a-kind. It became a pioneer of furniture that focuses on the material and allows you to feel the full quality of the material.

In 2013, we launched a premium version of the table. In 2013, we launched a premium version of the table, with a graft width of 10 cm or more, avoiding large knots and reducing the shade of color between the pieces of wood that are glued together. The limited amount of precious materials gives the table a richer look than the previous specifications.

In 2014, oil paint was added to the paint colors that were previously only available in urethane paint. This paint color goes well with the premium specification and allows natural materials to be used for a long time in a more natural state. Even if the chair is scratched, customers can maintain it by themselves and enjoy the change over time.

In addition, the lineup has been expanded with the introduction of wide-type chairs and benches with backs. With the introduction of wide type chairs and benches with backs, the product lineup was expanded, increasing the range of choices available to customers and becoming a series that can be selected according to the shape of the family and lifestyle.

More than ever, the world has come to expect the warmth of wood and the comfort of natural materials in its furniture and lifestyle. Until then, dining tables were made of veneered wood, but in 2010, solid wood tables with horizontal joints were introduced. The expression of the wood from the grain and knots is truly one-of-a-kind. It became a pioneer of furniture that focuses on the material and allows you to feel the full quality of the material.

In 2013, we launched a premium version of the table. In 2013, we launched a premium version of the table, with a graft width of 10 cm or more, avoiding large knots and reducing the shade of color between the pieces of wood that are glued together. The limited amount of precious materials gives the table a richer look than the previous specifications.

In 2014, oil paint was added to the paint colors that were previously only available in urethane paint. This paint color goes well with the premium specification and allows natural materials to be used for a long time in a more natural state. Even if the chair is scratched, customers can maintain it by themselves and enjoy the change over time.

In addition, the lineup has been expanded with the introduction of wide-type chairs and benches with backs. With the introduction of wide type chairs and benches with backs, the product lineup was expanded, increasing the range of choices available to customers and becoming a series that can be selected according to the shape of the family and lifestyle.

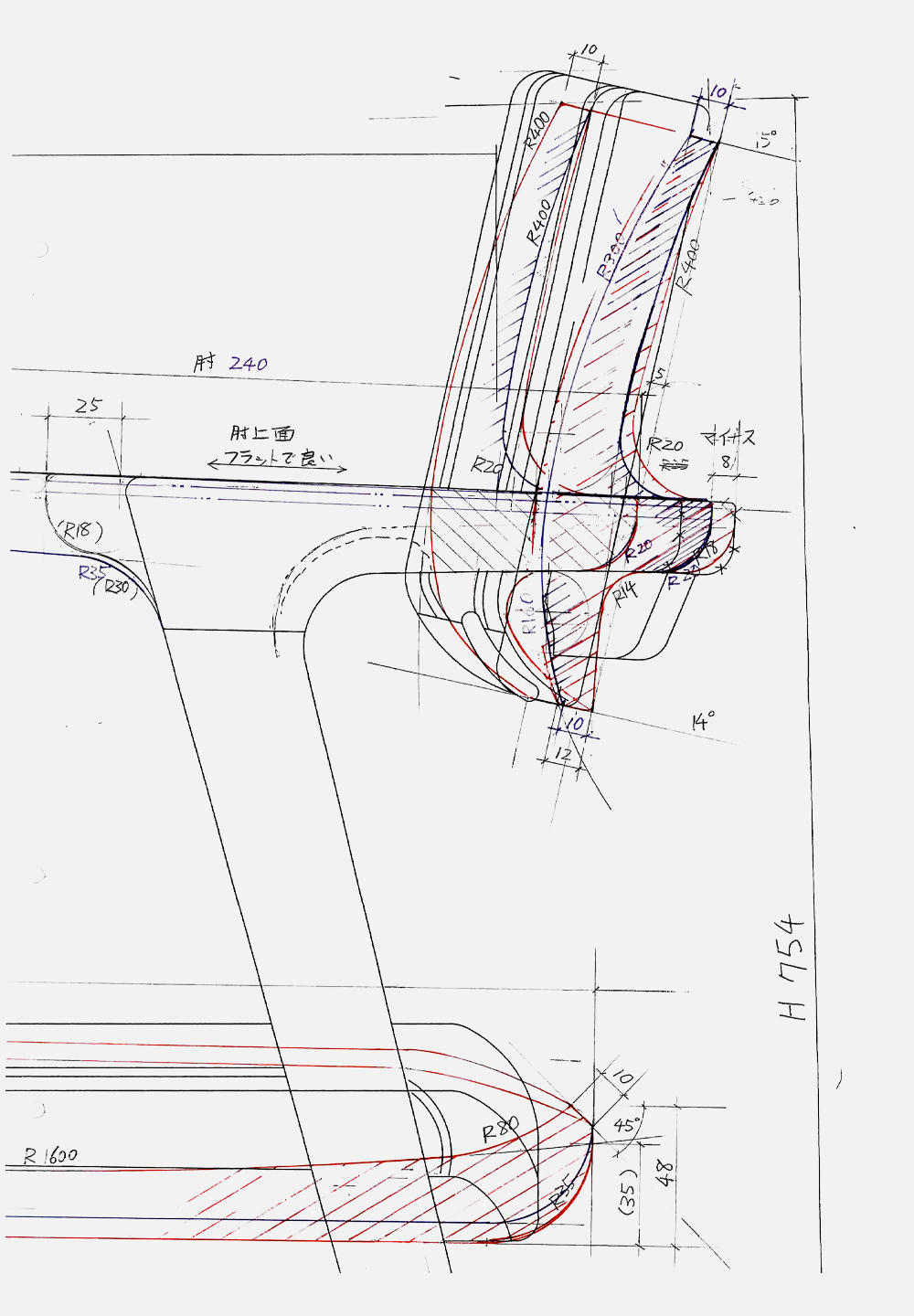

After 10 years on the market, Koti has already become one of FUJI FURNITURE’s iconic chairs, and to accelerate the momentum, we developed a new product in 2017. This is the All Solid Chair. The all-solid chair is not just a replacement of the previous cushion part with solid wood. We wanted the comfort and smoothness that only solid wood can provide, as well as the comfort of finely machined wood. The design was finalized through a series of revisions of the drawings by Kazushi Suzuki, followed by a series of manual processes by craftsmen. This chair is a further step forward for the Koti series, which is celebrating its 15th anniversary.

In 2018, an all-solid bench was introduced, which can be combined with the all-solid chair. In the same year, a covering version was added to the cushion type chairs and benches, resonating with the SDGs and promoting the development of products that can be used for a long time without having to be replaced.

The counter established a new style for dining room interiors. In response to the new living environment, where commercial interiors such as bars are incorporated into homes, we launched counter chairs in 2020, and in 2021, our 15th anniversary year, we are expanding our lineup with the launch of remodeled Koti LD chairs.

After 10 years on the market, Koti has already become one of FUJI FURNITURE’s iconic chairs, and to accelerate the momentum, we developed a new product in 2017. This is the All Solid Chair. The all-solid chair is not just a replacement of the previous cushion part with solid wood. We wanted the comfort and smoothness that only solid wood can provide, as well as the comfort of finely machined wood. The design was finalized through a series of revisions of the drawings by Kazushi Suzuki, followed by a series of manual processes by craftsmen. This chair is a further step forward for the Koti series, which is celebrating its 15th anniversary.

In 2018, an all-solid bench was introduced, which can be combined with the all-solid chair. In the same year, a covering version was added to the cushion type chairs and benches, resonating with the SDGs and promoting the development of products that can be used for a long time without having to be replaced.

The counter established a new style for dining room interiors. In response to the new living environment, where commercial interiors such as bars are incorporated into homes, we launched counter chairs in 2020, and in 2021, our 15th anniversary year, we are expanding our lineup with the launch of remodeled Koti LD chairs.

The Koti series has a number of specifications for chairs alone. There are cushions and solids, counter chairs and LD chairs. Wide type or bench type. You can choose the one that best suits your seating comfort, your interior design, and the shape that blends in with your family. They will give you the pleasure of creating your own ideal life, and you will grow so attached to them that you will not be able to let them go.

The frame can be selected from three types of wood: walnut, black cherry, and oak. The frame is available in three types of wood: walnut, black cherry, and oak, and each wood can be painted with oil or urethane, so you can find your favorite color that resonates with your heart.

For upholstery, you can choose from genuine leather, fabric, or soft leather in a total of 97 colors. There are an endless number of combinations to choose from, providing the best specifications for a wide range of people.

The appeal of Koti is further enhanced by the combination of materials, and the total sales volume of the Koti chair series has exceeded 55,000 units. The total sales of the Koti chair series have exceeded 55,000 units, and it has been successfully exported not only to Japan but also to other countries such as the United States and Switzerland.

What kind of life awaits us 10 to 20 years into the future, and how is Koti developing? Koti has continued to develop because its base design is a universally sought after design. So as long as people’s lives continue to change, Koti will also continue to evolve.

The appeal of Koti is further enhanced by the combination of materials, and the total sales volume of the Koti chair series has exceeded 55,000 units. The total sales of the Koti chair series have exceeded 55,000 units, and it has been successfully exported not only to Japan but also to other countries such as the United States and Switzerland.

What kind of life awaits us 10 to 20 years into the future, and how is Koti developing? Koti has continued to develop because its base design is a universally sought after design. So as long as people’s lives continue to change, Koti will also continue to evolve.

As time goes by and social networking sites become more and more popular, we choose furniture to suit our diverse interiors and lifestyles. For one trend, there is no such thing as everyone imitating it.

On the other hand, if you go back to the time of the bubble economy, popular and trendy products were prominent, and many people were looking for the same products. With the economy booming, there was no inventory left over, no matter how much we made.

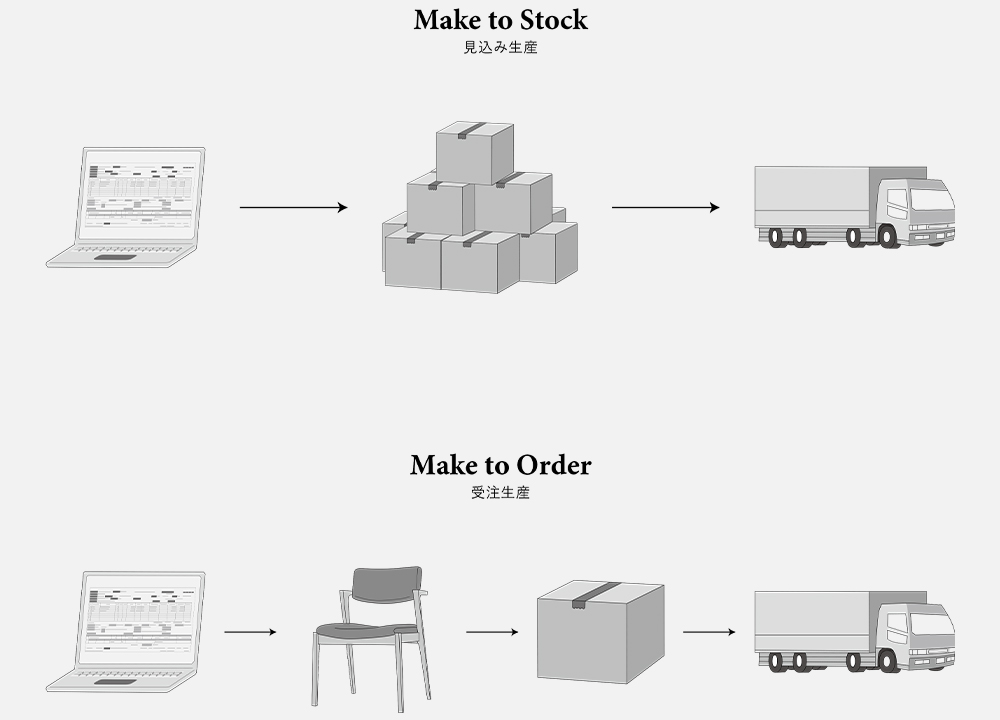

In order to deliver products to customers quickly, FUJI FURNITURE produced products in lots of parts in anticipation of the best-selling products.

Those days did not last long, and FUJI FURNITURE expanded its product lineup to meet the diversification of lifestyles, and the birth of Koti was one of them.

With the increase in the number of products, the inventory that had been produced in anticipation of the new product line was not able to meet the orders and became a prolonged dead stock.

The factory was overflowing with goods, and only the person in charge knew where everything was.

I want to change the status quo. With this strong desire, we started improvement activities based on the Toyota Production System. The most important guideline for improvement activities is “elimination of waste. The waste that occurs in a factory can be broadly classified into seven categories. There are seven major types of waste that occur in factories: waste from overproduction, waste from stagnation, waste from transportation, waste from processing itself, waste from inventory, waste from operation, and waste from creating defects. The elimination of waste is the process of finding out where these wastes appear and thoroughly eliminating them.

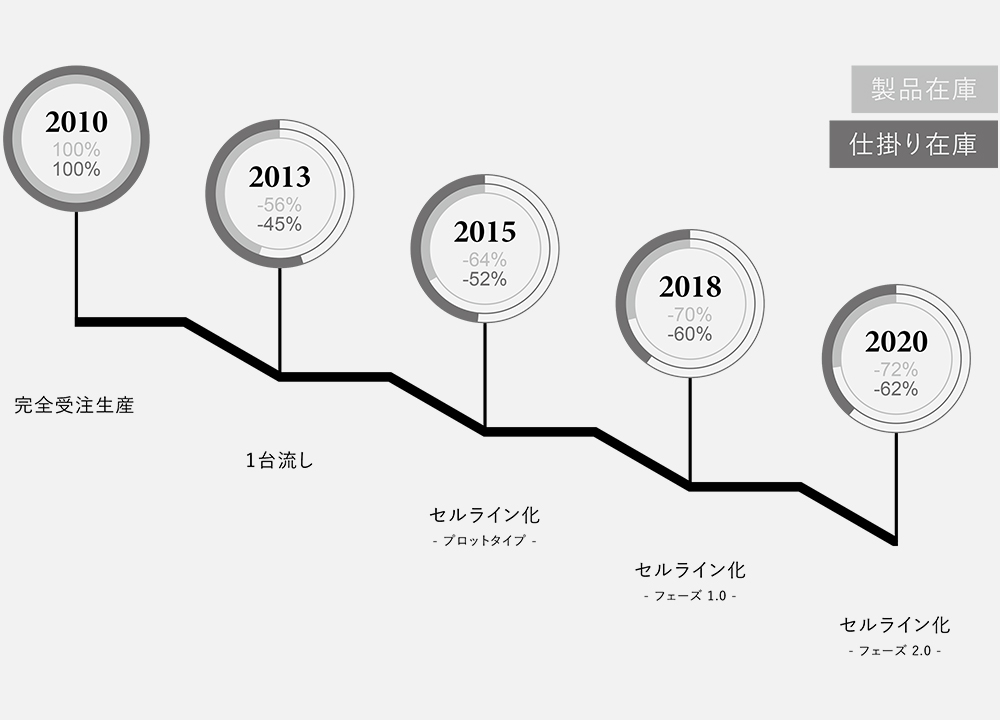

FUJI FURNITURE is taking steps to achieve higher quality, better cost performance, and shorter lead times through the elimination of waste. In order to “eliminate waste,” we have quit lot production of parts in anticipation of hot-selling products, and have switched to three production methods.

We produce only products that have been ordered by our customers. We switched to this method in order to eliminate the wastage of overproduction caused by prospective production. Unlike the previous production system, where we drew on inventory when an order came in, we started manufacturing each unit after receiving an order.

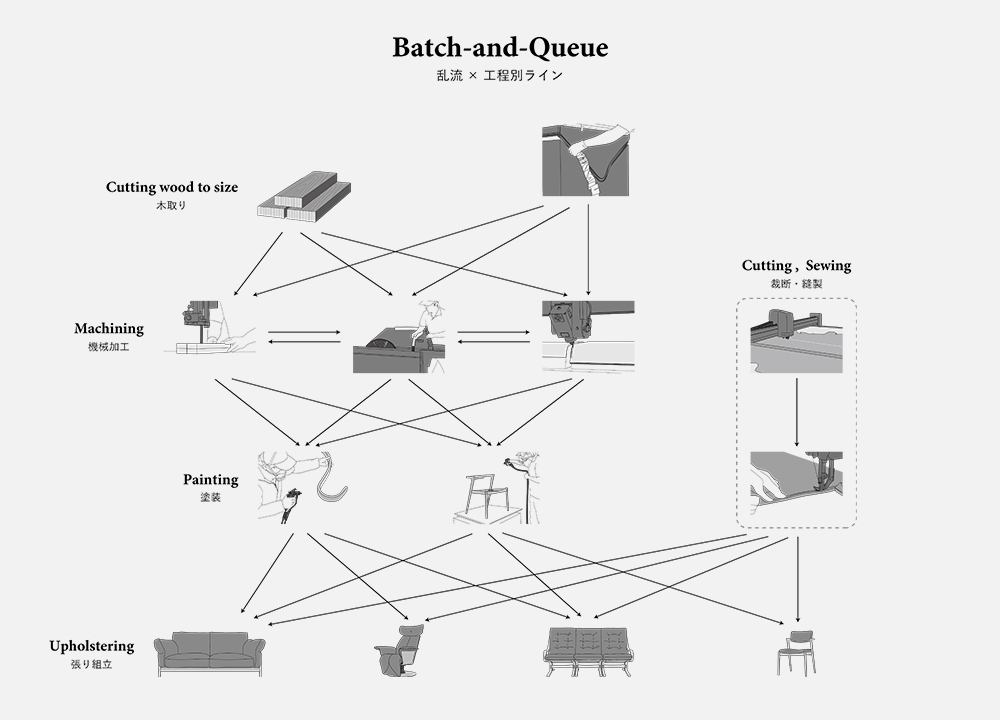

The factory at that time had a system suitable for lot production, and since each process produced parts for several product groups such as chairs and sofas, there was a large amount of work-in-process that stayed between processes. This led to overproduction waste, stagnation waste, and operation waste.

This is why we started the “single-unit flow” system. Based on the production control version of the final process, each process supplies the materials needed by the subsequent process, one unit at a time, at the necessary timing. This system eliminates the wastage of overproduction, stagnation, and wastage in operation.

In order to ensure just-in-time production of each unit, the processes for each product group, such as chairs and sofas, are standardized. In order to produce each unit just in time, the processes were standardized by product group, such as chairs and sofas, so that the status of the preceding and following processes could be understood, and work-in-processes between processes were reduced to the minimum.

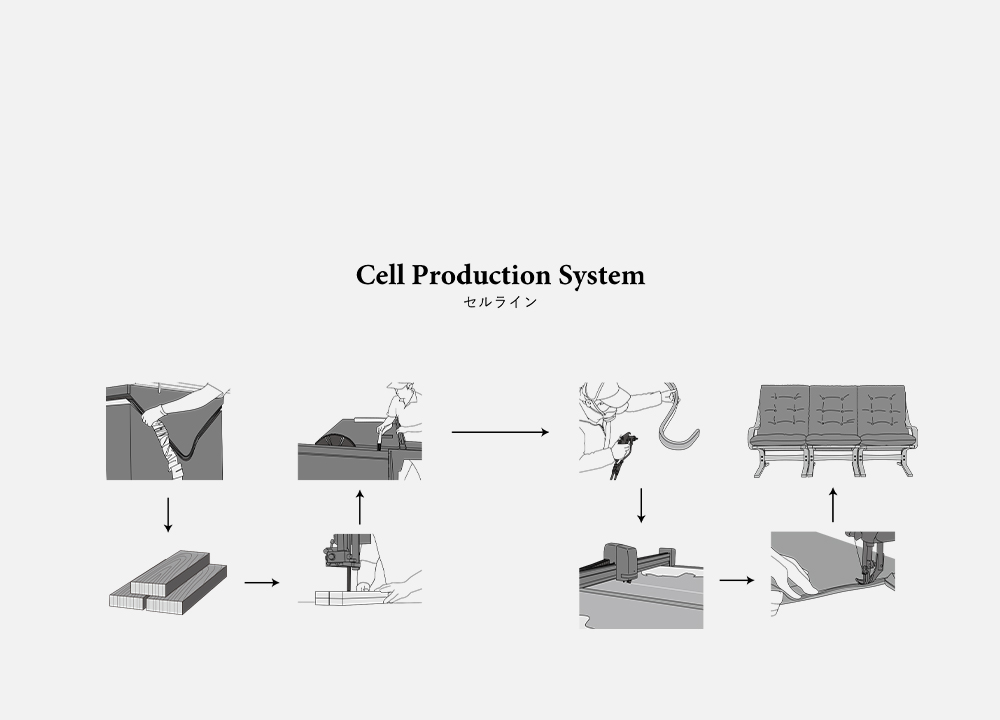

A cell line is a system that divides product groups into smaller groups and arranges processes in a circle with a small team. This will inevitably lead to mutual assistance between processes, further reduction of work-in-process, and shortening of production lead time.

A single-unit sink or cell line does not mean that production will continue with the layout once decided. By continuing to make repeated changes to the layout of our workplaces, we not only eliminate waste in transportation and waste in movement, but we have also established a system that can flexibly respond to changing order situations in response to the times.

There is no end to FUJI FURNITURE’s improvement efforts, and we believe that FUJI FURNITURE should achieve “12. Through our improvement activities and their results, we will protect the environment of the earth where we will live in the future.

In 2020, we were able to reduce product inventory by 72% and work-in-process inventory by 62%, assuming that the pile of product inventory and work-in-process inventory before the start of improvement activities was 100. This is the result of our improvement activities such as “Complete Built-to-Order Production”, “Single Unit Supply” and “Cell Line”.

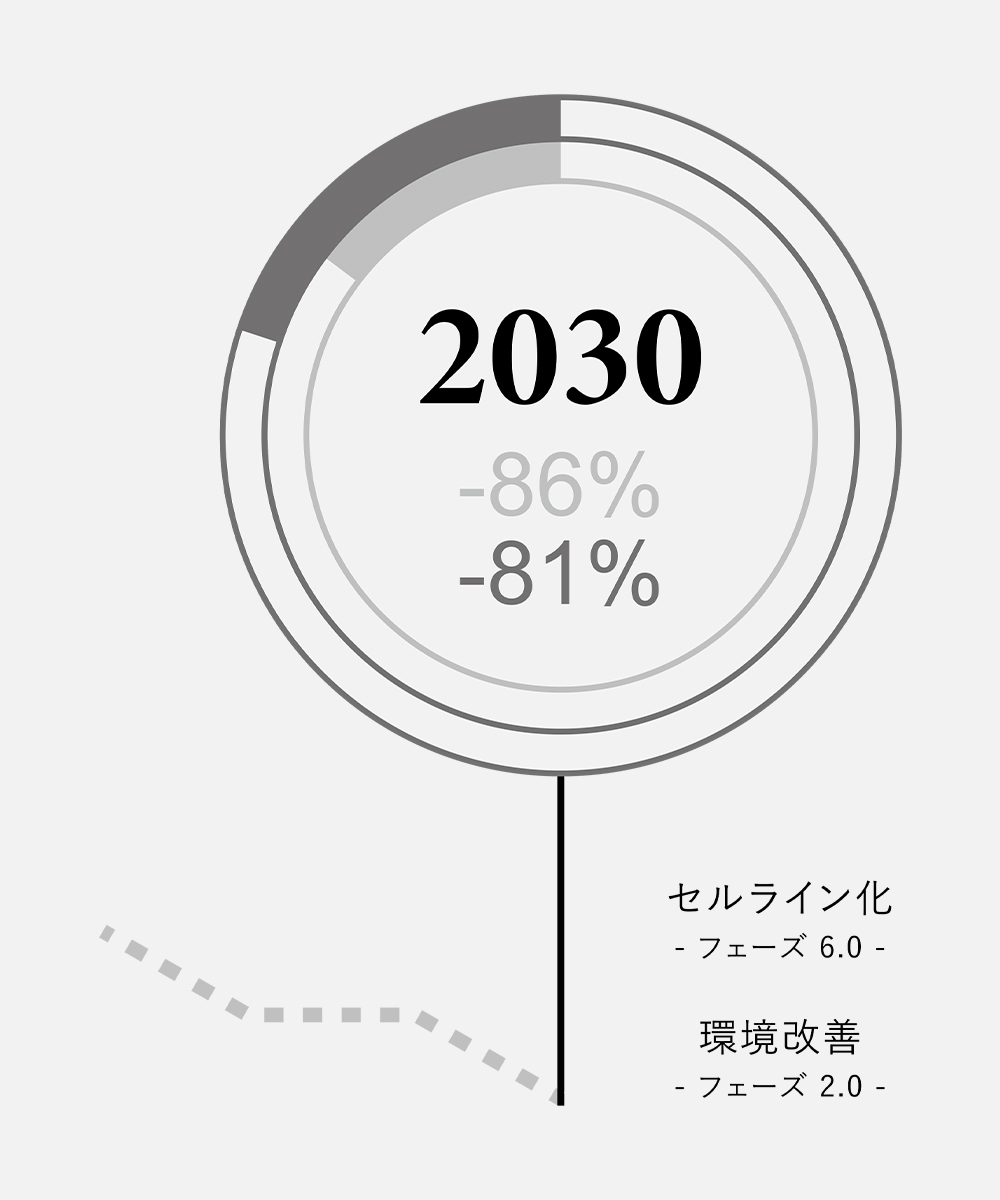

FUJI FURNITURE aims to reduce product and work-in-process inventories by an additional 50% from 2020 in order to achieve “12.

This is an extremely difficult goal to achieve, as it will require further improvements to our production system, which has improved dramatically since 2010. To achieve this goal, we will make improvements from two perspectives.

The first is the cell line, which is not yet complete at FUJI FURNITURE. The first is the “cell line”: FUJI FURNITURE’s cell line is not yet complete, and a cell line is not something that can be achieved simply by rearranging processes. In order to produce with a small team, it is necessary to pass on skills and to have one person who can perform multiple processes. In addition, the product groups that make up the production line need to be reviewed and adjusted many times. It is not enough to improve the production line alone; we must scrap and build the product lineup of FUJI FURNITURE, and brush up the products themselves.

Secondly, we need to improve the environment. Craftsmen use workbenches and carts to make sofas and tables. For example, if we can make all the movements of these objects horizontal, it will reduce the physical burden of lifting and carrying, and we can evolve into a work environment where people of all ages and genders can work for a long time. In addition, if we can visualize the production status of the lines, we can establish a system that allows the lines to help each other more. It is necessary to create an environment that combines such capital investment.

These are not improvements that can be completed in a single step, but will lead us to achieve our goals by repeating the PDCA cycle and going through multiple stages.

FUJI FURNITURE aims to reduce product and work-in-process inventories by an additional 50% from 2020 in order to achieve “12.

This is an extremely difficult goal to achieve, as it will require further improvements to our production system, which has improved dramatically since 2010. To achieve this goal, we will make improvements from two perspectives.

The first is the cell line, which is not yet complete at FUJI FURNITURE. The first is the “cell line”: FUJI FURNITURE’s cell line is not yet complete, and a cell line is not something that can be achieved simply by rearranging processes. In order to produce with a small team, it is necessary to pass on skills and to have one person who can perform multiple processes. In addition, the product groups that make up the production line need to be reviewed and adjusted many times. It is not enough to improve the production line alone; we must scrap and build the product lineup of FUJI FURNITURE, and brush up the products themselves.

Secondly, we need to improve the environment. Craftsmen use workbenches and carts to make sofas and tables. For example, if we can make all the movements of these objects horizontal, it will reduce the physical burden of lifting and carrying, and we can evolve into a work environment where people of all ages and genders can work for a long time. In addition, if we can visualize the production status of the lines, we can establish a system that allows the lines to help each other more. It is necessary to create an environment that combines such capital investment.

These are not improvements that can be completed in a single step, but will lead us to achieve our goals by repeating the PDCA cycle and going through multiple stages.

FUJI FURNITURE’s mission is “to make everyone the hero of their lives through the value created by creative destruction “.

Creative destruction is not only about creating new furniture designs, but also about breaking the status quo and proactively adopting new systems through daily efforts such as improvement activities and environmental maintenance, which are part of our corporate culture.

Driven by a spirit of inquiry, ambition, and unity, we have successfully implemented new production methods, such as completely made-to-order production and single-unit production, and are actively working toward our goal of 2030. In addition, we offer our customers a wide range of choices in design, wood species, and upholstery, and deliver the joy of knowing that each piece they choose is made for them.

出展アイテムリスト

D03780AOWFO13 detail

D03780NOWFO13 detail

D04520AOWFO13 detail

D04520NOWFO13 detail

D04460AOW detail

D04460NOW detail

D04590NOWFO13 detail

D04600AOWFO13 detail

D03780SOWFO13 detail

D03780NBPLS27 detail

D04520NBPLS27 detail

D04460NBP detail

D03780UBPLS27 detail

D04520UBPLS27 detail

D03780SBPLS27 detail

design by Kazushi Suzuki designer profile