In 2023

In 2023

The history of molded plywood dates back to ancient Egypt around 3500 BCE. To address the scarcity of high-quality wood, craftsmmen began creating plywood products using thin sheets of timber. This innovative technique has been refined over the centuries, and since the early 20th – when it was embraced by many architects and designers – its use in furniture has expanded significantly. Pursuing more beautiful forms from an ergonomic and design perspective, these pioneers conducted extensive research to enhance its applications. Molded plywood is considered to be a gift born from the collective wisdom and skills of many people.

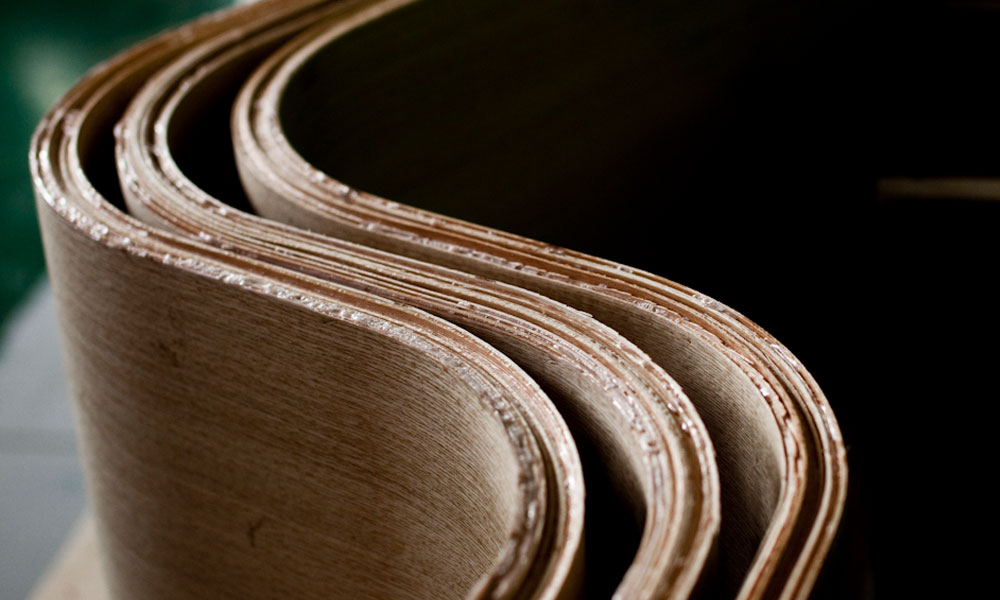

Molded plywood is essentially layered plywood that has been bent into shape. Layered plywood consists of thinly sliced sheets of wood called venees, which are stacked together. Using this technique, bold and graceful curves can be created, allowing for various expressive designs. It also enable the appreciation of the natural wood characterists, like unique grain pattersn, expecially in bent wood pieces. This is a technique makes it possible to craft lightweight and durable wooden products with elegant curves that are challending to achieve with solid wood.

Fuji Furniture’s journey with molded plywood began in 1977. Inspired by Scandinavian molded plywood products, we embarked on developing our own techniques. Even after more that 20 years, our molded plywood technology continues to evolve. Here, we reflect on the histroy of Fuji Furniture’s molded plywood, along with the technologies used in the products we’ve developed so far.

Although we began working with the new technology of molded plywood, the journey was a continuous process of trial and error due to the delicate precision required in its processing. Every factor—from selecting veneers and coatings to adjusting the applied pressure and heat, and fine-tuning according to changes in humidity and ambient temperature—affected the final result, leading us to repeatedly create prototypes.

About a year after we began our efforts, in 1978, we released Fuji Furniture’s first molded plywood product, Rosetta. The frame, which integrated the seat frame with the front legs and the back frame with the rear legs, was unusual in the furniture industry at the time from the standpoint of durability.

Rosetta quickly became a popular product after its release, and in the following year, 1979, we released Memory, which became the prototype for today’s Agio. Within a few years of their release, both Rosetta and Memory recorded sales that rivaled the sofa sets, which were Fuji Furniture’s main products at the time.

After that, we developed many products using molded frames, expanding the breadth of our product lineup.

During the peak of Japan’s economic bubble, the total coordination of living and dining spaces became mainstream. Molded plywood products continued to evolve, leading to the release of numerous living and dining items. A new product series called Stream, featuring molded plywood designs, was established. Subsequently, housing environments shifted to an LD (Living-Dining) style, integrating living and dining spaces. Stylish products became favored, further advancing the development of dining chairs using molded frames. As a result, Fuji Furniture came to be known as synonymous with molded plywood.

At the beginning of the 2000s, following the collapse of the bubble economy and amid rising demand for low-priced imported furniture, consumer preferences becam polarized into low-priced and high-priced segments. At Fuji Furniture, to differentiate ourselves from low-priced imported furniture, we were compelled to evolve by elevating the techniques we had cultivated up to that point.

During this period of transition, our first product using molded plywood that incorporated three-dimensional curved surfaces, Tapio, was born. For Fuji Furniture at that time, it became a revolutionary product. Without editing software capable of handling 3D drawings, creating the envisioned curved surfaces required enormous eddot. We had to dissect the molded plywpood into cross-sections at 2mm intervals to create molding press jigs, among other labor-intensive tasks. Moreover, adjustments to the applied pressure and heat demanded us to apply our existing know-how in many ways, making the path to completion anything but easy. However, the charm of Tapio, completed with its beautifully smooth curved surfaces, remains undiminished event today.

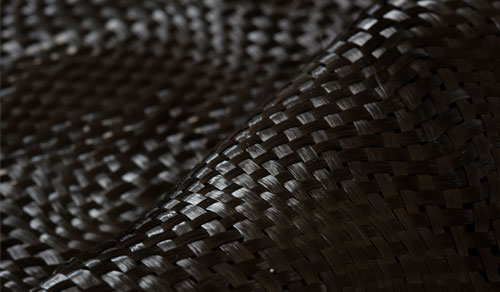

Carbon is an element found in a wide range of substnaces, from diamonds to graphite. When this carbon is formed into fibres, it becomes carbon fiber.Carbon fiber is lightweight and has high strencgth; in particular, its tensile strength in the fiber direction is up to ten times that of steel. CFRP (Carbon Fiber Reinforced Plastics), which is carbon fiber solidified with resin, began market development in the 1980s, and in recent years, demand has rapidly increased in areas such as sports equipment, aerospace, and automotive industries.

In 2014, Fuji Furniture also began researching whether such materials could be utilized in furniture. The example we chose was Agio, which can be considered the origin of Fuji Furniture’s molded plywood. Generally, it is believed that combining wood with dissimilar materials to create composites disrupts the balance of strength and results in loss of stability. Therefore, we began the research somewhat skeptically, but as we progressed, we discovered that combining CFRP with molded plywood produced properties that complement each other’s weaknesses.

Not only did it become possible to suppress the wood’s characteristics of deformation and warping due to aging, maintaining shape stability, but the tensile strength, which is the strength of carbon fiber, suppressed material breakage in the bent parts of molded plywood. This allowed us to maintain the same strength as conventional products even when reducing the thickness of the molded plywood by about 30–40%. As a byproduct of making it thinner, it also provided an unprecedented springiness. While there are still challenges, such as increased costs and more complex processes, there are high expectations for the expansion of designs using molded plywood in the future.

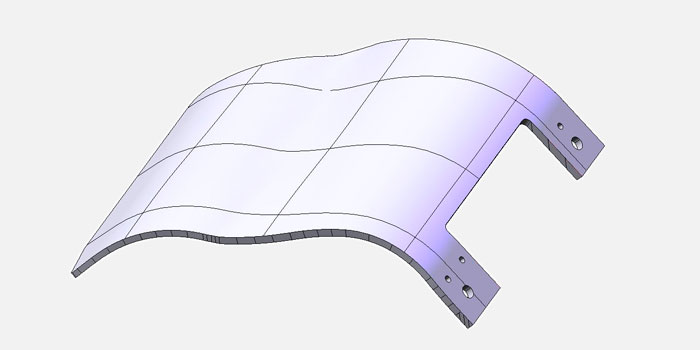

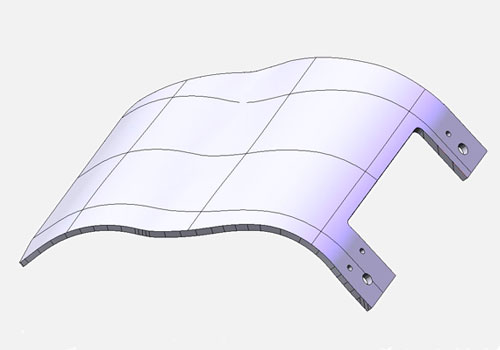

Fuji Furniture’s molded plywood uses thermosetting resin and adopts a manufacturing method that applies pressure by sandwiching the material between large curved surfaces. However, by utilizing thermoplastic film encountered at an overseas trade fair in 2015, it became possible to use wooden molds with various curved surfaces, allowing us to shape molded plywood in ways that were not possible before.

Thermosetting resin is liquid, and moreover, it requires stainless steel or copper plates that serve as electrodes for curing. Therefore, it was necessary to apply pressure to the veneers constituting the molded plywood on a single continuous surface. However, since thermoplastic film is, as its name suggests, a thin film, it can be processed prior to applying pressure. Additionally, because the film is melted in a hot press before pressing, electrodes are not needed during the pressing process. As a result, it became possible to create products with multiple curved surfaces.

While there are challenges—such as how the material moves and post-molding processing methods due to applying pressure simultaneously on multiple curved surfaces—the ability to mold with large curvatures enables us to tackle shapes that were difficult to realize until now.

In recent years, the development of products that combine solid wood carving and molded plywood has been progressing. From a production standpoint, solid wood carving and molded plywood have different manufacturing processes and lead times, so they were rarely combined as main components of a product. However, with the introduction of a high-performance CNC machining center in 2015, we established a system capable of accurately mass-producing solid wood, eliminating the difference in lead times, and in 2018, the Nagi dining chair was born. Not only did we have the new equipment, but we also had already built up know-how over more than 40 years in molded plywood technology to stabilize warping and twisting, which was a major factor in its creation. The combination of a solid wood back frame with beautiful wood grain and a seat frame characterized by its rounded silhouette has been gaining popularity since its launch and is becoming the new face of Fuji Furniture.

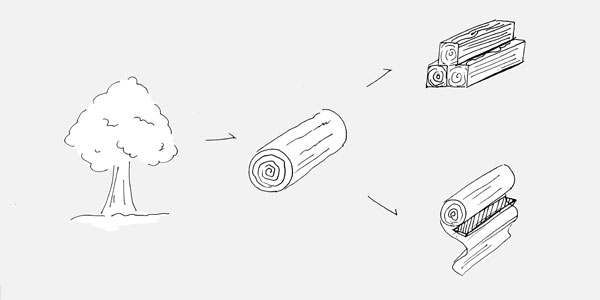

Veneers are cut according to the furniture being manufactured.

Veneers are cut according to the furniture being manufactured.

Addhesive is applied to the veneers and they are stacked together.

Addhesive is applied to the veneers and they are stacked together.

The stacked veneers are placed into a mold.

The stacked veneers are placed into a mold.

Using machinery, they are pressed and formed.

Using machinery, they are pressed and formed.

They are removed from the mold.

They are removed from the mold.

Parts are then cut out.

Parts are then cut out.

1977-

At our company, we began our efforts in technological development in 1977, and the first production we attempted was uniform-thickness molded plywood, which invoolves bending the material while maintained a consisten thickness. This is the most standard processing method and is widely used not only for painted components but also for structural parts and more.

1985-

This method involves molding by inserting wooden pieces called “koma” (wooden blocks) to create branches in curved shapes. Compared to methods that join individual parts, such as mortise and tenon joints or dowel joints, forming an integrated molded frame where the parts are unified allows for the creation of stronger products. However, unlike simple uniform-thickness molding, the way heat is transmitted in the “koma” parts becomes complex, and because pressing must be done from multiple directions, controlling pressure and temperature becomes difficult. The use of “koma” is applied not only to seat parts but also to handle parts to make it easier to grip when standing up or sitting down.

1988-

The characteristic of “ookoma” (large koma) inserted molded plywood is that it allows for more branching points. Typically, one “koma” enables three branches, but an “ookoma” can accommodate four branches. Due to the substantial and heavy finish, at that time, it was used for leg frames of desks and conference tables. However, like the standard “koma” insertion molding, this technology also required various innovations due to factors such as the thermal conductivity of the “koma” parts and the increased number of branching points affecting the precision of the molding jigs and the method of applying pressure during pressing.

2006-

This method involves removing the “koma” that were inserted during molding after the molding process is complete. It became possible to create the backrest, arms, and even legs—all parts that were previously impossible to produce—as a single frame, allowing us to achieve lightweight designs that can only be realized with molded plywood. The technology of removing the “koma” may sound simple when put into words, but it is actually a more difficult technique than solidifying them in place. We achieved this by repeatedly conducting research, referencing overseas technologies as well as, of course, through domestic prototyping.

2006-

This is a method where the thickness is adjusted during molding, such as making the edges of the mold thinner or thicker toward the ends. The length of each individual veneer sliced to about 1.5 mm thickness and the order of lamination are set to align with the jig. A process called “scarfing” is applied to the parts where the veneers are cut in the middle and joined, thinning the edges of the 1.5 mm veneers further at an angle like a slope to prevent gaps during molding.

Despite the many preparatory steps involved, the most challenging aspect is that the way heat is transmitted changes due to differences in thickness. Thin parts conduct heat easily, while thick parts do not. If heating is adjusted to the thick parts, the thin parts may become overcooked. By overcoming these challenges, the resulting molded frames are lightweight and allow for freer designs with fewer constraints.

2008-

3D surface plywood refers to plywood formed with three-dimensional curved surfaces. It enables twisting that is difficult with two-dimensional curved molded plywood, allowing for even smoother curved surfaces. Compared to regular molded plywood, the way pressure is applied tends to become uneven, and curvature designs that distribute the material’s expansion and contraction due to compression are required. Despite these challenges, it is a technology that can accommodate highly sophisticated designs.

2009-

This is a method where the branching point in in “koma” insert molding are increased to two. It is employed in the frames of dining chairs.

By branching the koma, we have achieved stability in terms of strength while keeping the design slender and lightweight. However,m having two koma makes the management of heat and pressure, as well as the production procedures, even more complex, requiring skilled techniques in the process.

2015-

This is a method that uses CFRP—carbon fiber solidified with resin, employed in sports equipment, automobiles, and other applications—as a composite material. Although using dissimilar materials increases the manufacturing processes, it can maintain the same durability at about 60% of the usual thickness, and in addition to being lightweight, it offers a flexible springiness.

2017-

This is a plywood technology that uses a film-like adhesive that melts with heat. Unlike conventional thermosetting types, it does not require electrodes in the molding press mold, making it possible to perform high-curvature bending and bending in defferent directions on a single board, rainsing expectations for use in new shapes.

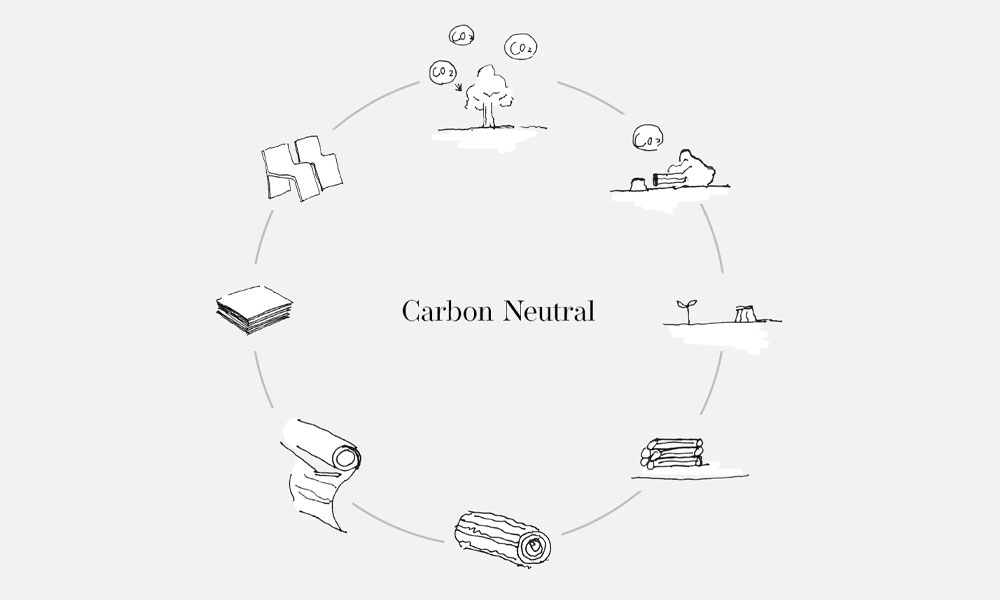

Carbon neutrality means maintaining a constant total amount of carbon emitted and carbon absorbed. In Japan, various initiatives are being promoted based on the ‘2050 Carbon Neutral Declaration’ announced in 2020. Reforestation is known as a familiar initiative. Plants are recognized as good for the environment because of the mechanism of photosynthesis, where they absorb carbon dioxide and emit oxygen. Therefore, it tends to be thought that the more reforestation progresses, the more carbon dioxide on Earth decreases while oxygen increases, leading to environmental improvement. However, when considered at the atomic level, we find that our understanding of the relationship between reforestation and environmental issues is mistaken.

Let’s unravel the reasons why reforestation is encouraged, even though increasing reforestation does not directly reduce the amount of carbon dioxide on Earth.

It is believed that the total amount of atoms composing substances like oxygen and carbon dioxide (oxygen atoms and carbon atoms) remains constant on Earth. Therefore, a state where oxygen becomes saturated and carbon dioxide drastically decreases cannot occur.

Through photosynthesis, plants decompose water (H₂O) absorbed from their roots and leaves and carbon dioxide (CO₂) absorbed from the air, generating carbohydrates like starch necessary for growth. Since oxygen is unnecessary in this production, it is released into the atmosphere. At first glance, it may seem that the carbon and hydrogen used in the plant’s growth have disappeared, but in reality, it is correct to consider that they have been accumulated within the plant. Therefore, if plants are burned, the accumulated carbon becomes carbon dioxide and is released back into the atmosphere. In other words, atoms like oxygen and carbon are cycling.

For reforestation to have a positive impact on the environment, it is essential that it is conducted in a cycle where the circulation of atoms can occur appropriately.

To balance the circulation of atoms in the atmosphere, the timing and number of trees planted are, of course, important, but equally important is properly managing, harvesting, and utilizing grown trees. So, when is the appropriate timing for harvesting?

Taking broadleaf trees, which are widely used in furniture, as an example, it takes about 40 to 50 years from planting saplings until they can be used as timber. Once a tree reaches its peak growth, it no longer requires as much carbon, which was essential for its growth, so the speed of carbon accumulation decreases. This turning point is considered the optimal timing for harvesting.

Harvested timber is transformed into many familiar items, not only furniture but also house pillars and more. By promoting harvesting and utilization that match the growth speed of trees, we can effectively sequester carbon.

The yield of veneers used in molded plywood is as high as 60% of the log, making it known as an eco-friendly material. Furthermore, molded plywood can be expected to be used stably and for a long time because it reduces the defects of wood.

Hammerhead

An majestic personal chair modeled after a hammerhead shark. Wrapped in molded plywood from the back to the armrests, this masterpiece holds its own in any executive space. The seat uses molded urethane with durability and elasticity. When reclining, it offers a solid sense of security, creating a space where you can focus on reading or desk work.

The wood grain that flows along the curves of the headrest and back is elegant and smooth.

The spacious armrests allow you to indulge in moments of luxurious.

The wood grain that flows along the curves of the headrest and back is elegant and smooth.

The spacious armrests allow you to indulge in moments of luxurious.

Den

“Den” combines the meanings of a study, a children’s play area, and a large, splendid building. The back lavishly uses a single piece of molded plywood, giving it presence and dignity as a personal chair while stylishly coordinating the voluminous cushions. The armrest boards are just the right size for resting your hands, and the curve under the armrests makes sitting and standing look elegant. The armrests and cushions, which evoke a playful spirit, lightly enhance the study space. The meticulous attention hidden within its substantiality enhances the quality of life.

Den

“Den” combines the meanings of a study, a children’s play area, and a large, splendid building. The back lavishly uses a single piece of molded plywood, giving it presence and dignity as a personal chair while stylishly coordinating the voluminous cushions. The armrest boards are just the right size for resting your hands, and the curve under the armrests makes sitting and standing look elegant. The armrests and cushions, which evoke a playful spirit, lightly enhance the study space. The meticulous attention hidden within its substantiality enhances the quality of life.

The contrast between the three-dimensional cushions and the thinness of the molded plywood creates an exquisite balance.

The design that seems to envelop your back accentuates the beauty of the wood grain.

The contrast between the three-dimensional cushions and the thinness of the molded plywood creates an exquisite balance.

The design that seems to envelop your back accentuates the beauty of the wood grain.

Tapio

A beautiful form of three-dimensional curves woven by over 40 years of cultivated technology. The undulating curves connecting the arms to the seat envelop the cushions, giving a cohesive unity that tightens the overall design. This beautiful silhouette blends into the space, as if time is flowing leisurely. The warm, nature-embracing Scandinavian style is filled with affection for each individual user and consideration for nature.

This sofa was born by sublimating the knowledge and know-how of molded plywood accumulated over about 30 years into technology.

The generous yet soft Tapio

that embraces us in every era.

This sofa was born by sublimating the knowledge and know-how of molded plywood accumulated over about 30 years into technology.

The generous yet soft Tapio

that embraces us in every era.

Agio

A sectional sofa that has been loved for over 40 years. It is a flagship product representing FUJI FURNITURE’s molded plywood. Since the initial model, it has undergone seven minor changes, and its appeal in design, functionality, comfort, and more is immeasurable. The flexibility of the molded plywood and the appropriate seating angle allow you to relax with peace of mind. Being lightweight makes rearrangement easy, and with a wealth of variations, you can create a sofa shape that suits the user.

Agio

A sectional sofa that has been loved for over 40 years. It is a flagship product representing FUJI FURNITURE’s molded plywood. Since the initial model, it has undergone seven minor changes, and its appeal in design, functionality, comfort, and more is immeasurable. The flexibility of the molded plywood and the appropriate seating angle allow you to relax with peace of mind. Being lightweight makes rearrangement easy, and with a wealth of variations, you can create a sofa shape that suits the user.

Usually used as a large sofa.

To lie down alone is luxurious time spent.

Usually used as a large sofa.

To lie down alone is luxurious time spent.

For simplicity, the layout is freely adjustable.

It creates various scenes.

For simplicity, the layout is freely adjustable.

It creates various scenes.

Individual parts can also be interchanged.

Discover the layout that is perfect for you.

Individual parts can also be interchanged.

Discover the layout that is perfect for you.

Likke

We shaped our desire to brighten spaces and bring comfort to people. The elegant line of the armrest connecting the back to the legs enhances its sophistication, and the unequal pressure molding that tapers towards the leg tips presents a sleek overall appearance. By integrating the back and seat frames through koma insert molding and using fabric springs that balance strength and lightness, we have achieved a weight as light as approximately 4.2 kg.

The frame lines that sway like the wind

are beautiful from any angle, enveloped in clear air.

The frame lines that sway like the wind

are beautiful from any angle, enveloped in clear air.

Calm

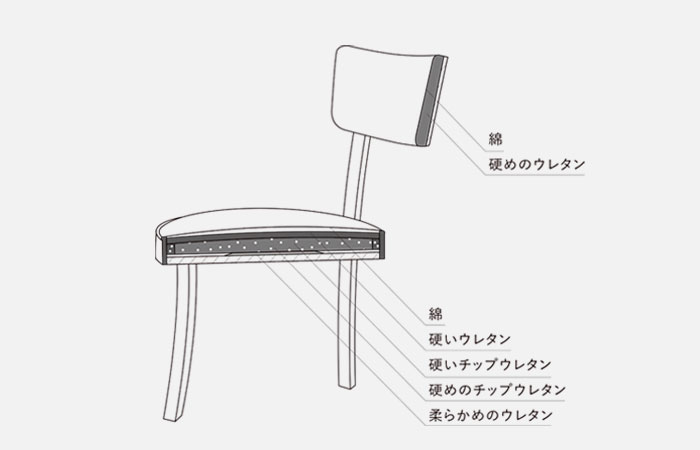

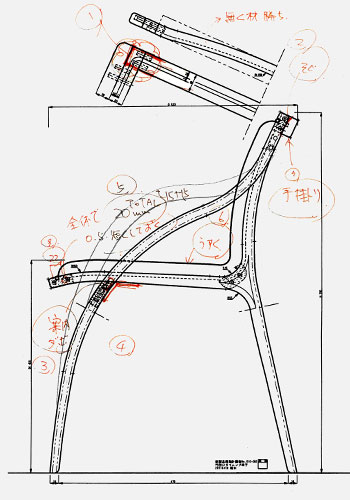

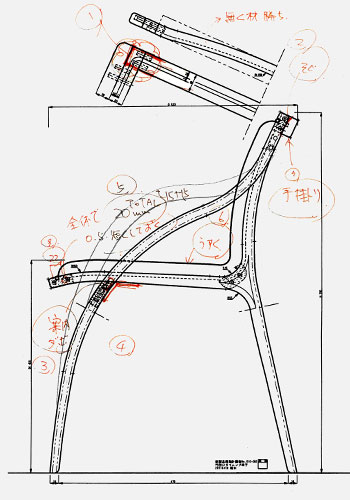

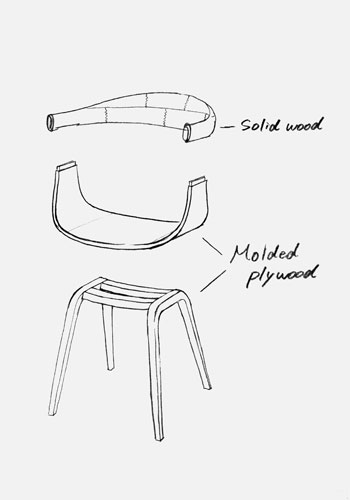

At approximately 3.6 kg for the armchair and about 3.2 kg for the armless chair, this is the lightest chair at FUJI FURNITURE. Through the technology of double koma molding, we’ve made it possible to finish the backrest, seat, and legs in a single frame. The slightly undulating seat is designed to follow the contours of the body, providing support to distribute body pressure even with thin urethane. Developed under the idea that dining chairs, which are sat on every day, should be as light as possible, Calm brings richness to people’s lives.

Calm

At approximately 3.6 kg for the armchair and about 3.2 kg for the armless chair, this is the lightest chair at FUJI FURNITURE. Through the technology of double koma molding, we’ve made it possible to finish the backrest, seat, and legs in a single frame. The slightly undulating seat is designed to follow the contours of the body, providing support to distribute body pressure even with thin urethane. Developed under the idea that dining chairs, which are sat on every day, should be as light as possible, Calm brings richness to people’s lives.

With the goal of reducing the product weight to just 3 kg, we advanced the development.

We meticulously reviewed the design, adjusting the dimensions of the seat board and frame in millimeters.

While it has a sleek and lightweight appearance, stable strength is ensured.

With the goal of reducing the product weight to just 3 kg, we advanced the development.

We meticulously reviewed the design, adjusting the dimensions of the seat board and frame in millimeters.

While it has a sleek and lightweight appearance, stable strength is ensured.

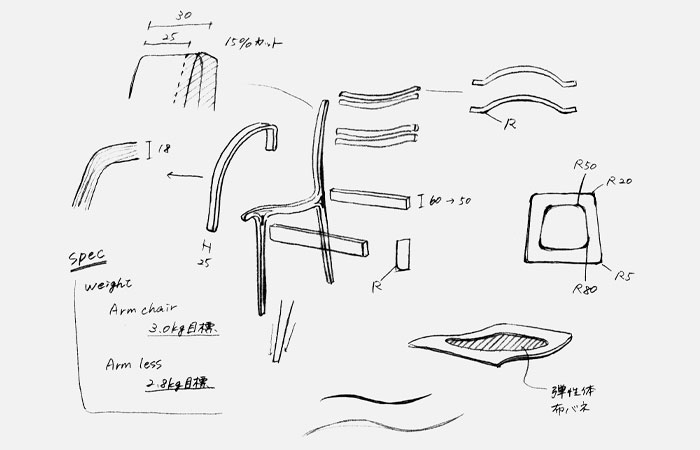

Nagi

A chair that fuses long-cultivated molded plywood technology with solid wood carved using newly introduced equipment. The seamless curves from the back to the arms are so inviting that you can’t help but want to touch them. The generously rounded, spacious seat is designed for comfort, making it hard to get tired even after sitting for long periods, providing a seating experience that fits your body well. The supple and gentle shape born from the resonance of multiple curves warmly illuminates your dining space.

The cushion that seems to cling to the line of the seat is a pleasant finish to look at.

The uncompromising attention to detail imbues the design with beauty.

The cushion that seems to cling to the line of the seat is a pleasant finish to look at.

The uncompromising attention to detail imbues the design with beauty.

Cute

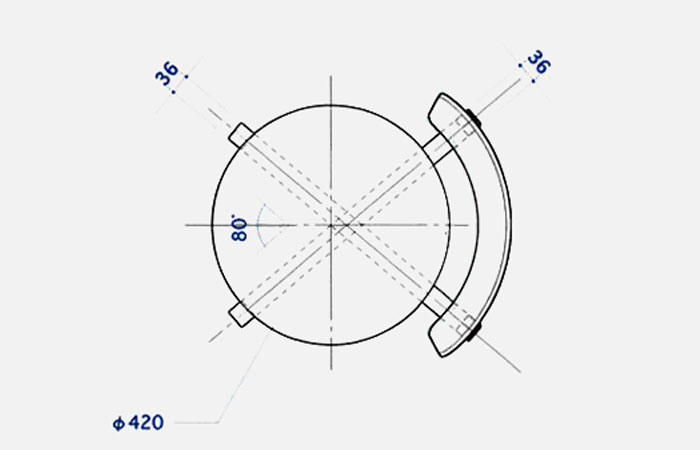

A chair that simplifies the Rococo-style image using molded plywood. The large backrest draws the sharpest curve at FUJI FURNITURE, allowing you to feel a better fit to your body. The legs have a design where two frames cross each other, increasing strength, and the parts called “nuki” (stretchers) that are usually necessary are removed. It is a compact yet detail-oriented shape that brings together knowledge and technology.

Cute

A chair that simplifies the Rococo-style image using molded plywood. The large backrest draws the sharpest curve at FUJI FURNITURE, allowing you to feel a better fit to your body. The legs have a design where two frames cross each other, increasing strength, and the parts called “nuki” (stretchers) that are usually necessary are removed. It is a compact yet detail-oriented shape that brings together knowledge and technology.

By adjusting the angle and intersection position of the crossed legs, we achieved a graceful form while maintaining strength.

The seamless frame using koma insert molding

enhances the beauty of the chair.

By adjusting the angle and intersection position of the crossed legs, we achieved a graceful form while maintaining strength.

The seamless frame using koma insert molding

enhances the beauty of the chair.