In 2024

In 2024

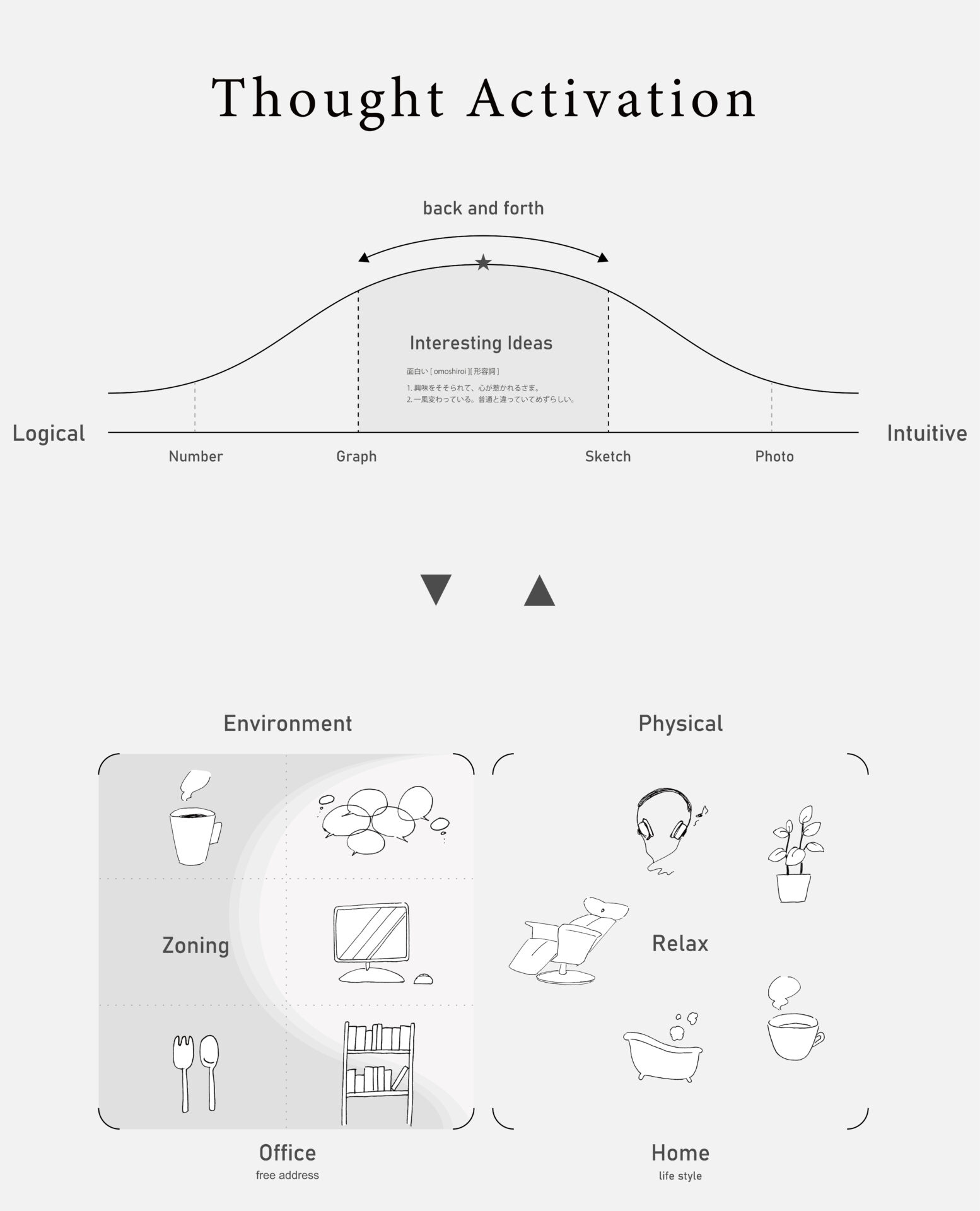

In your everyday life, do you ever suddenly come up with interesting ideas?

Whether it’s in the bath, during a walk, or while chatting with friends—the scenes vary from person to person—but isn’t the common point that these are all relaxation times? Even when we feel that our brains are resting, they continue to think subconsciously, and it is said that when we are relaxed, our thinking is activated.

Just as we sit at the dining table to eat, when we want to generate ideas, it’s necessary to consciously create that environment. As one way to achieve this in the office space, we propose introducing recliners into the office. Recliners, which allow you to relax immediately by changing your posture, can soften people’s thinking and, we believe, become a factor that leads to the initiation of innovation.

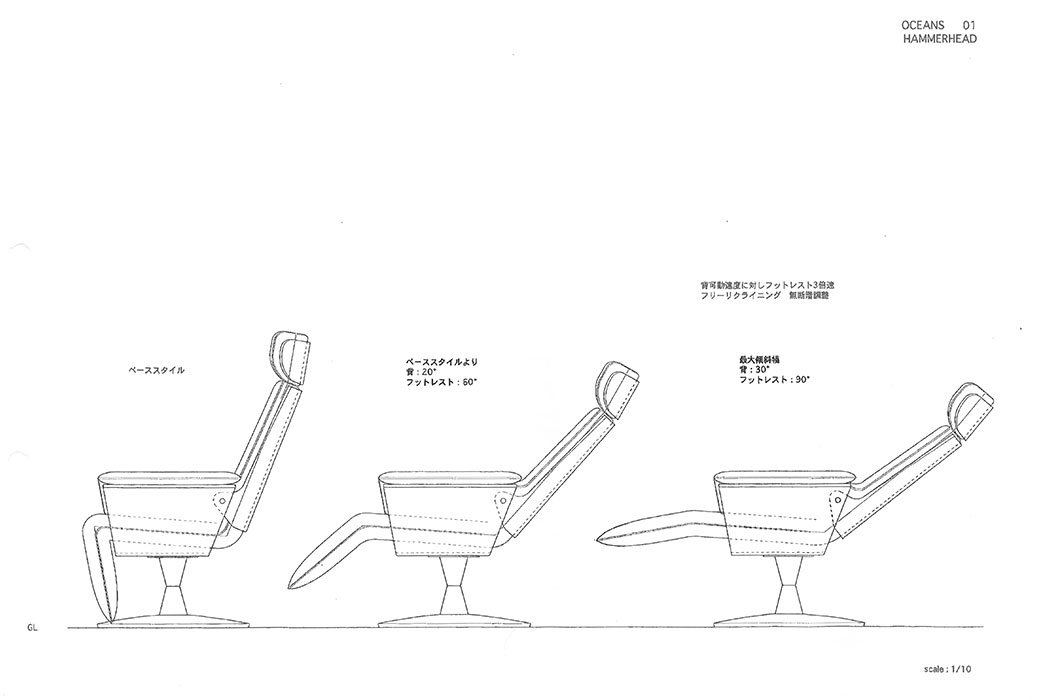

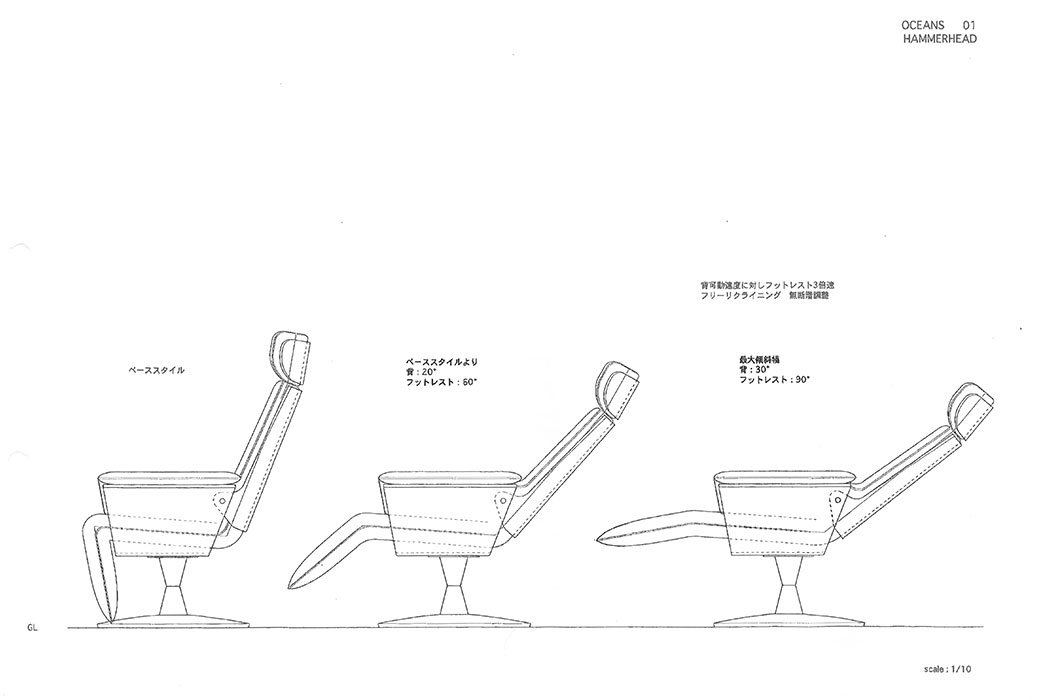

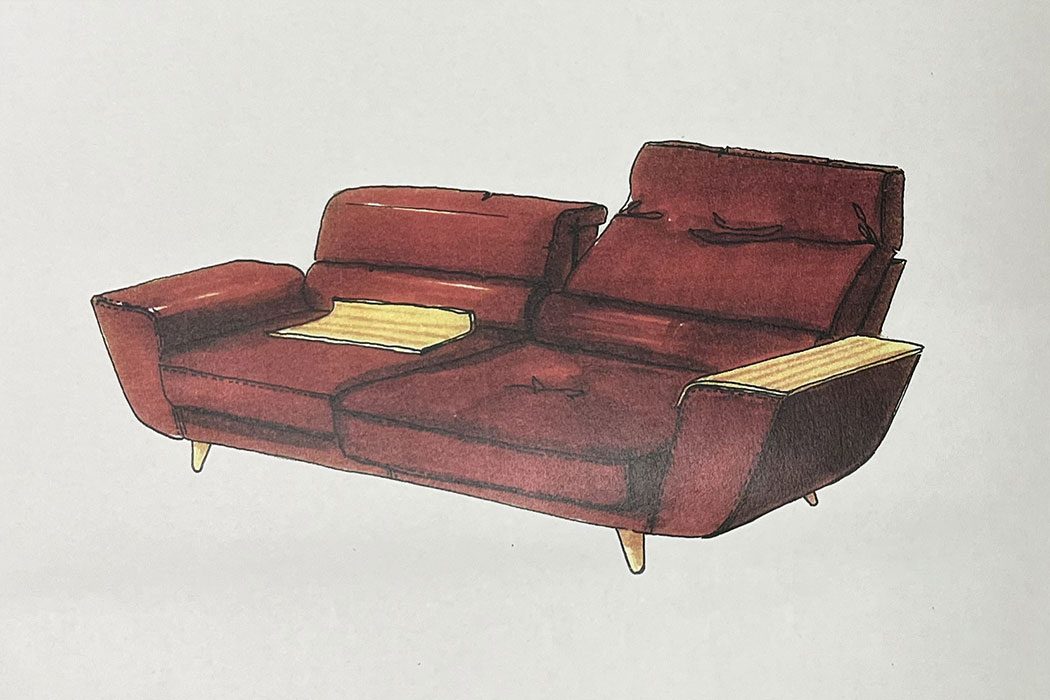

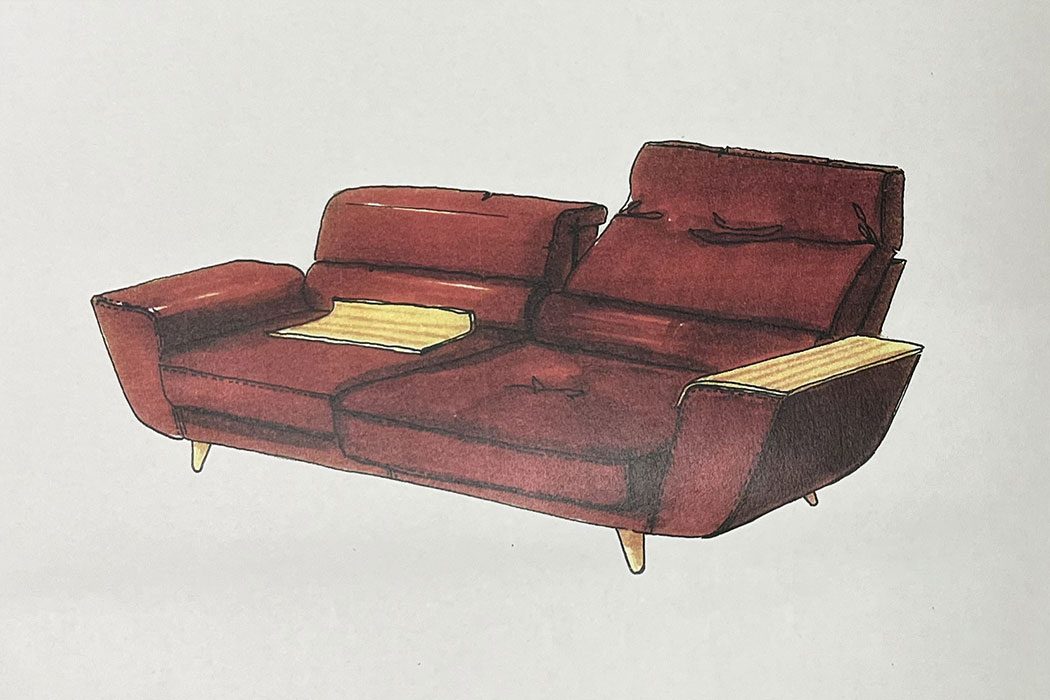

Hammerhead, inspired by the hammerhead shark that swims majestically in the ocean.

We projected onto the recliner the hammer-shaped form of its head extending left and right, and the smooth curves unique to marine creatures. Each component is given a sense of presence, and with a seat width of 450 mm, it feels comfortably spacious when seated, regardless of body size. The luxurious space and relaxation time guided by the design contribute to truly fulfilling moments.

Dolphin captures the image of a dolphin diving into the sea while swimming underwater.

Not only did we use motifs like the sharp mouth that hints at its predatory agility and the dynamic fins, but by shaping it into a spindle form—thicker in the middle and tapering toward the front and back—we projected the vibrancy of life specialized in fast swimming onto the recliner. The gentle roundness of the details born from the fully upholstered design evokes the cute impression of dolphins. The seat width is set at 445 mm, providing a reassuring fit that conforms to the body. The thoughtfulness shaped by the design supports a time where you can calmly concentrate.

Kangu is designed with the motif of a penguin leisurely walking on ice.

The wings that enable fast swimming without flight, along with thick subcutaneous fat and dense feathers that allow survival in extreme cold, shape their majestic appearance. By harmonizing the refined silhouette of the wooden frame, the firm cushions, and the soft touch created by multiple organic curves with the essence of the word “relax,” we have redefined a recliner that feels truly comfortable. The embracing presence brought by the design allows tension and flexible thinking to coexist in the office, building an environment where you can fully immerse yourself.

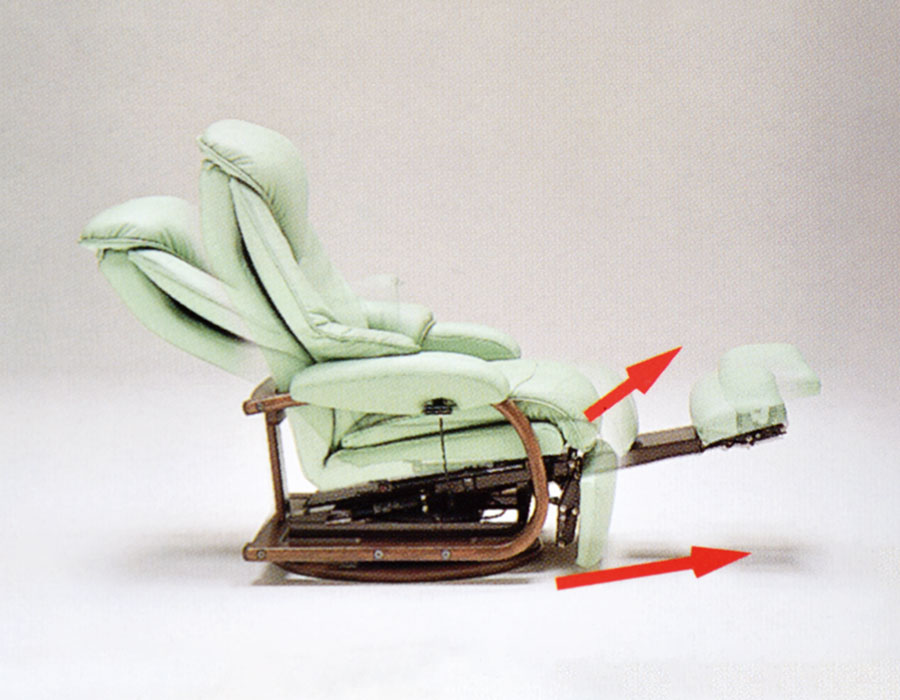

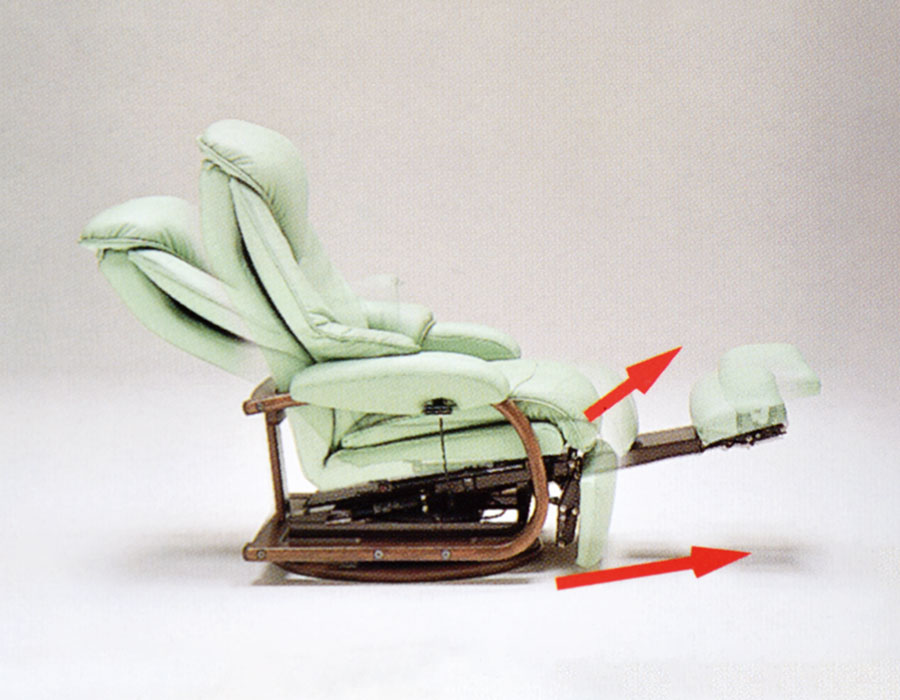

The recliners in the Oceans series use an original mechanism jointly developed by FUJI FURNITURE and Ichinotsubo Manufacturing.

By utilizing this original mechanism, the Oceans series recliners can easily recline to a full-flat position by pulling the lever and shifting your body weight, without any discomfort. Returning the lever allows you to lock it at your preferred reclining angle, and the footrest rises in conjunction with the back angle. While enabling intuitive operation, the recliner does not reveal the presence of the mechanism. At the time of development, recliners capable of full-flat positions existed on the market, but their mechanisms were visibly prominent and gave a rugged impression. The original mechanism is a crucial element in achieving high functionality without compromising the recliner’s refined design. We will introduce the intensive development process that led to the beautiful fusion of this original mechanism with the recliners in the Oceans series.

In 2008, FUJI FURNITURE had two significant aspirations: “We want to create a ‘new’ recliner unlike any before” and “We want to develop commemorative products for our 50th anniversary in 2009.” These aspirations were abstract and vague, not yet at the starting point. Just as we were grappling with these ideas, we met Designer Masaru Kato from SHOCK DESIGN, a company specializing in interior design, product design, and graphic design. We requested SHOCK DESIGN to propose designs for our recliner series. The recliners, featuring full-flat specifications that promise a satisfying relaxation and eye-catching designs that seamlessly blend the concept with the furniture, aligned perfectly with our two major aspirations. This marked the beginning of developing our original mechanism.

In 2008, FUJI FURNITURE had two significant aspirations: “We want to create a ‘new’ recliner unlike any before” and “We want to develop commemorative products for our 50th anniversary in 2009.” These aspirations were abstract and vague, not yet at the starting point. Just as we were grappling with these ideas, we met Designer Masaru Kato from SHOCK DESIGN, a company specializing in interior design, product design, and graphic design. We requested SHOCK DESIGN to propose designs for our recliner series. The recliners, featuring full-flat specifications that promise a satisfying relaxation and eye-catching designs that seamlessly blend the concept with the furniture, aligned perfectly with our two major aspirations. This marked the beginning of developing our original mechanism.

Designer Masaru Kato of SHOCK DESIGN was born in 1973. He spent three years of high school in Denmark, returned to Japan to enter and graduate from an art university, and after joining a furniture manufacturer in Hida-Takayama, he began working as SHOCK DESIGN in Copenhagen, Denmark. As an all-rounder in product, interior, and graphic design, he has been proposing designs to various companies.

The Oceans series proposed by Designer Kato in 2008 began when he was captivated by the powerful whirlpool of the Naruto Strait, famous for the Naruto Bridge connecting Awaji Island and Tokushima, during his journey to the FUJI FURNITURE factory. In addition to recliners like Hammerhead and Dolphin, and side tables like Remora, the series also included recliners such as Manta and Lobster, sofas like Crab, and side tables like Octopus. All recliners shared a refined design that subtly concealed the mechanisms inspired by marine creatures, and full-flat specifications that promised supreme relaxation were required.

At FUJI FURNITURE, we had been continuously developing various recliners. Ten years ago, in 1998, we developed a double-action footrest mechanism that could raise the footrest to an even higher position from the extended state of a regular footrest. The footrest and reclining functions operated independently, broadening the range of comfort. Even as of 2024, this mechanism continues to receive high praise.

While we continued developing multiple recliners, we faced three main challenges with our recliners:

1. Discomfort in the backrest: At that time, when reclining, the seat moved forward to match the tilting backrest, causing the contact point between the back and the seat to shift. This resulted in clothing wrinkles and a less comfortable seating experience, necessitating unconscious adjustments.

2. Reclining angle: We were unable to create recliners that could recline to a full-flat position, enhancing the comfort of relaxation.

3. Weighty design aesthetics: Existing recliners had mechanisms that were prominently visible, giving a bulky impression. Their box-like designs were far from the refined aesthetics expected of furniture pieces.

At FUJI FURNITURE, we had been continuously developing various recliners. Ten years ago, in 1998, we developed a double-action footrest mechanism that could raise the footrest to an even higher position from the extended state of a regular footrest. The footrest and reclining functions operated independently, broadening the range of comfort. Even as of 2024, this mechanism continues to receive high praise.

While we continued developing multiple recliners, we faced three main challenges with our recliners:

1. Discomfort in the backrest: At that time, when reclining, the seat moved forward to match the tilting backrest, causing the contact point between the back and the seat to shift. This resulted in clothing wrinkles and a less comfortable seating experience, necessitating unconscious adjustments.

2. Reclining angle: We were unable to create recliners that could recline to a full-flat position, enhancing the comfort of relaxation.

3. Weighty design aesthetics: Existing recliners had mechanisms that were prominently visible, giving a bulky impression. Their box-like designs were far from the refined aesthetics expected of furniture pieces.

In developing the full-flat mechanism, we aimed to have the back, seat, and foot parts interlock to achieve reclining angles close to horizontal, allowing for seamless adjustments of the reclining angle without steps. By interlinking each part, we aimed to provide the comfort of lying on a bed.

While full-flat recliners existed in the market at that time, none combined a light and airy appearance with functional specifications. Therefore, through the development of our original mechanism, we addressed the three challenges of recliners and aimed to develop products that aligned with Designer Kato’s vision.

In developing the original mechanism for the full-flat specification, we sought the cooperation of Ichinotsubo Seisakusho Co., Ltd. Founded in 1948, Ichinotsubo Seisakusho has consistently engaged in OEM manufacturing of steel products. From development, design, procurement of materials, pressing, welding, painting, assembly, to shipping, all processes are conducted at our own domestic factories located in Nara Prefecture and Mie Prefecture. With high technical expertise and a meticulous approach to manufacturing, along with rigorous quality control and environmental preservation, Ichinotsubo Seisakusho has been sought after by various industries as a result of the meticulous efforts built up over 75 years since its founding. Within a relatively short development period, they dedicated intense time to realizing FUJI FURNITURE’s vision down to every detail.

In developing the original mechanism for the full-flat specification, we sought the cooperation of Ichinotsubo Seisakusho Co., Ltd. Founded in 1948, Ichinotsubo Seisakusho has consistently engaged in OEM manufacturing of steel products. From development, design, procurement of materials, pressing, welding, painting, assembly, to shipping, all processes are conducted at our own domestic factories located in Nara Prefecture and Mie Prefecture. With high technical expertise and a meticulous approach to manufacturing, along with rigorous quality control and environmental preservation, Ichinotsubo Seisakusho has been sought after by various industries as a result of the meticulous efforts built up over 75 years since its founding. Within a relatively short development period, they dedicated intense time to realizing FUJI FURNITURE’s vision down to every detail.

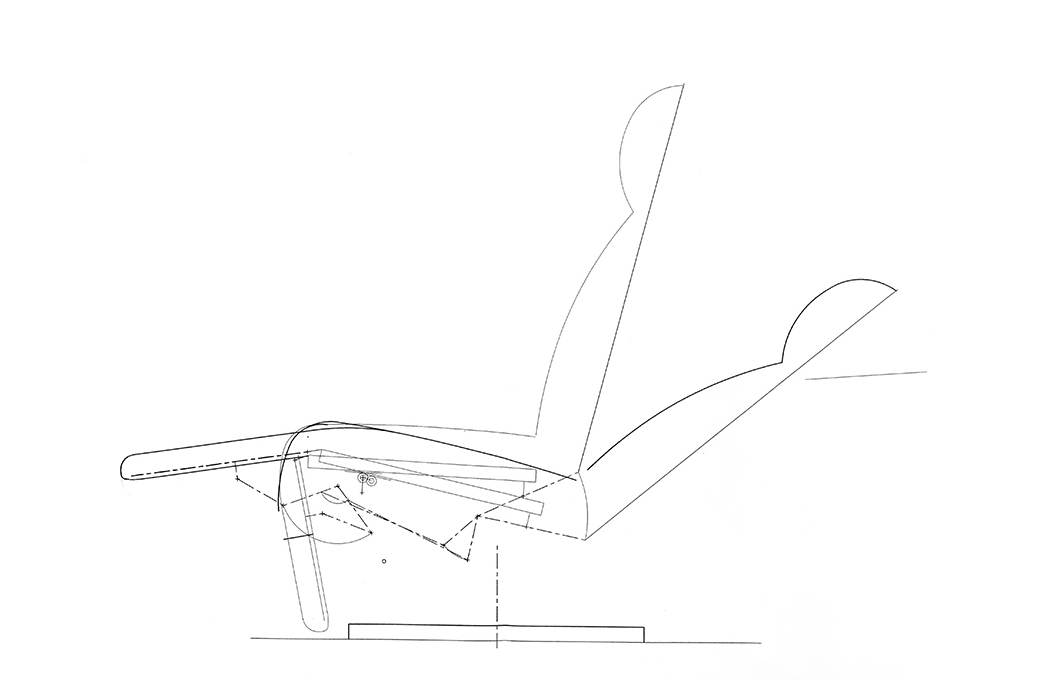

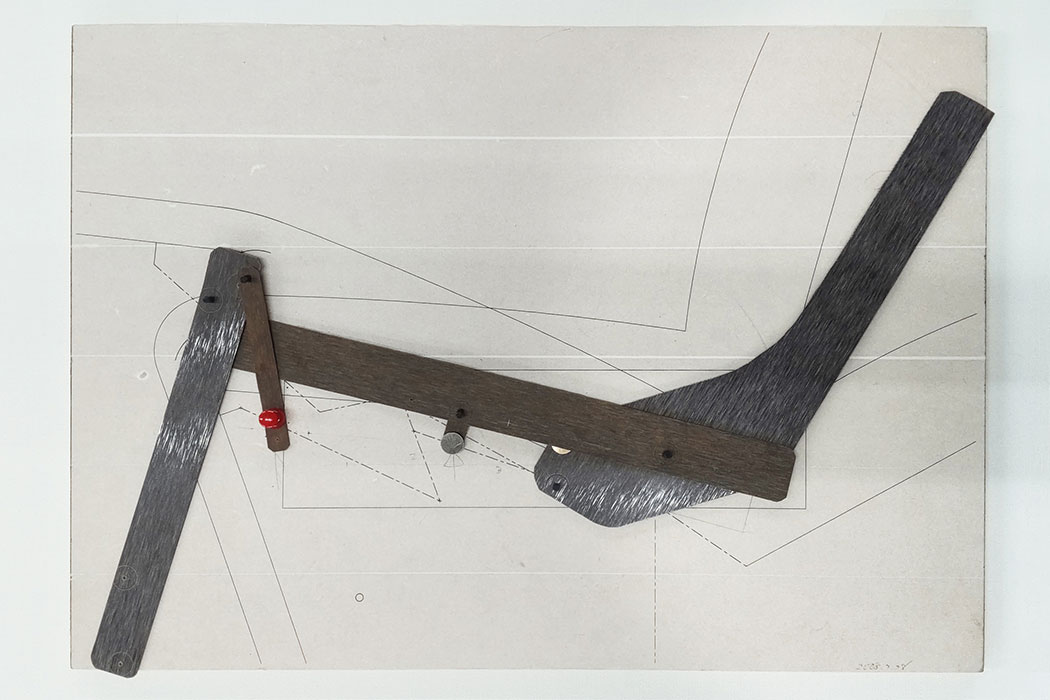

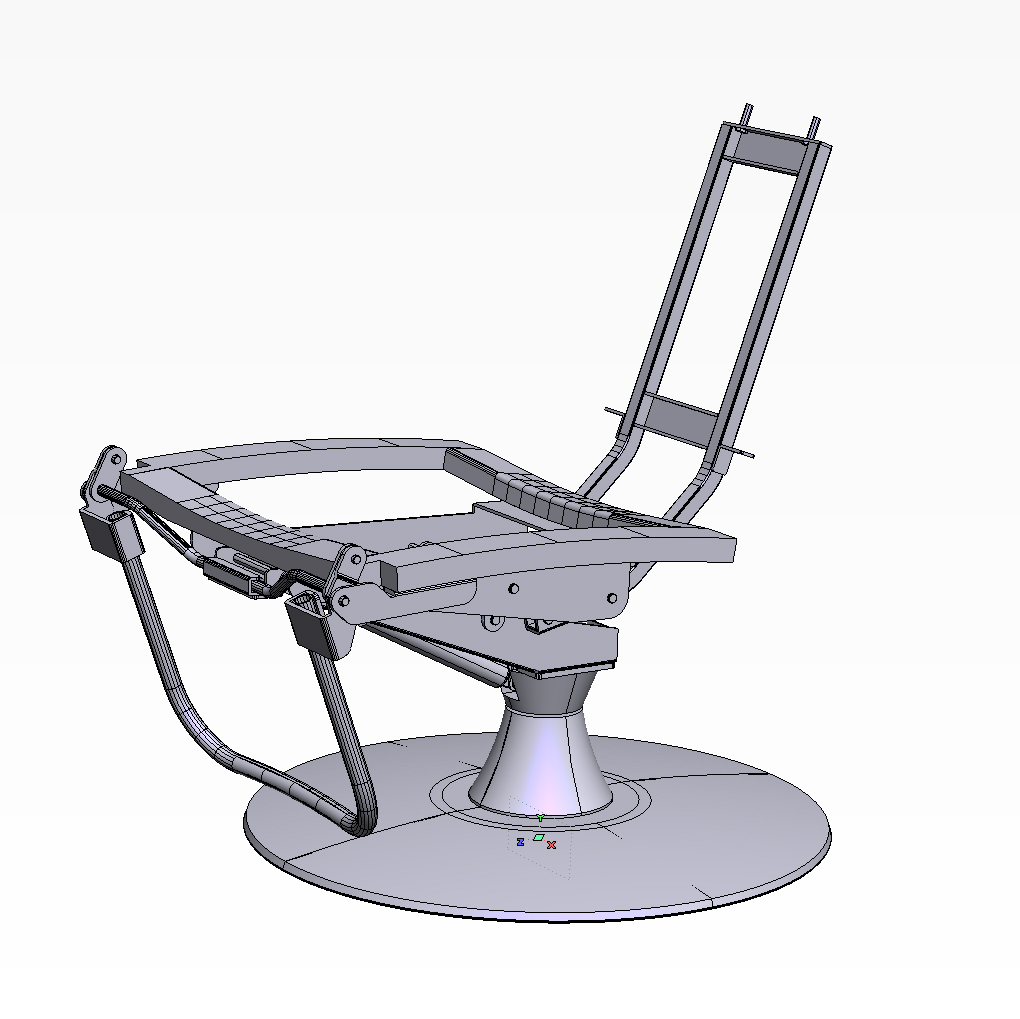

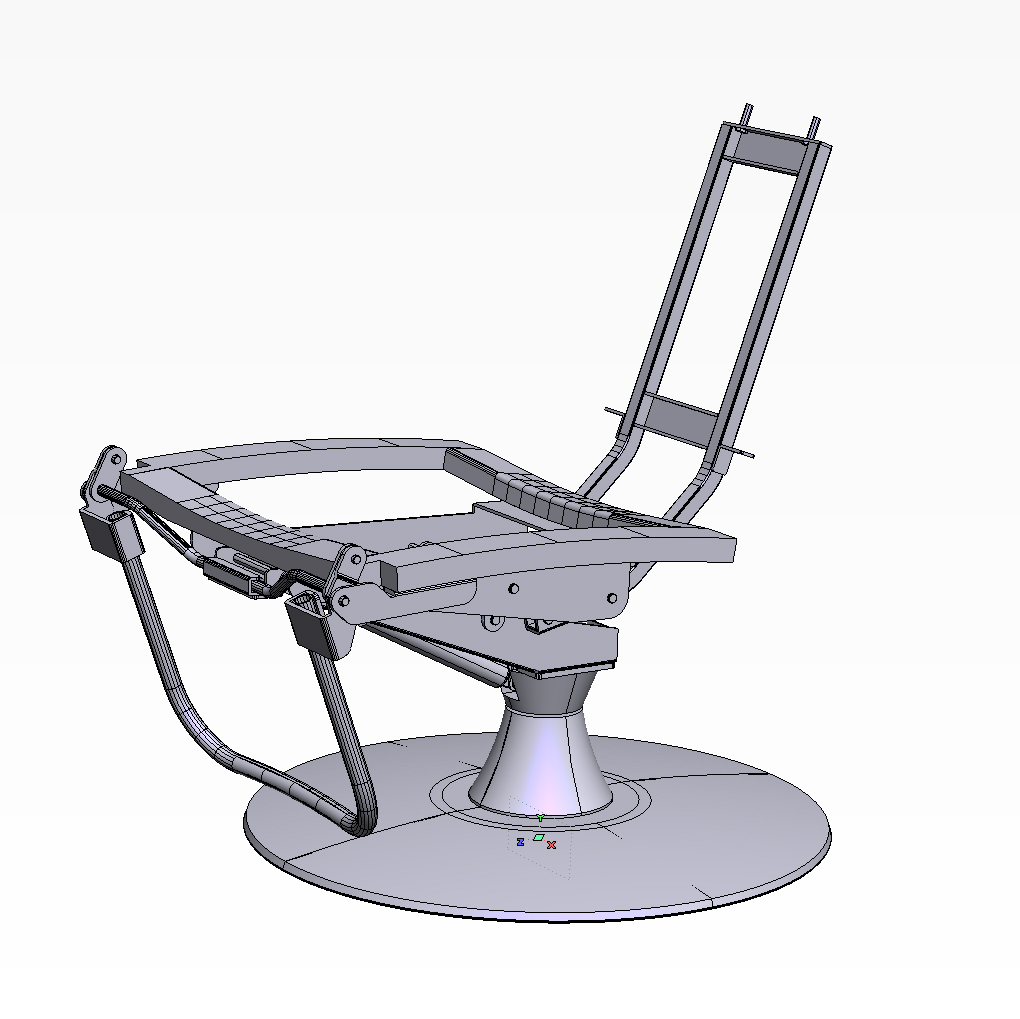

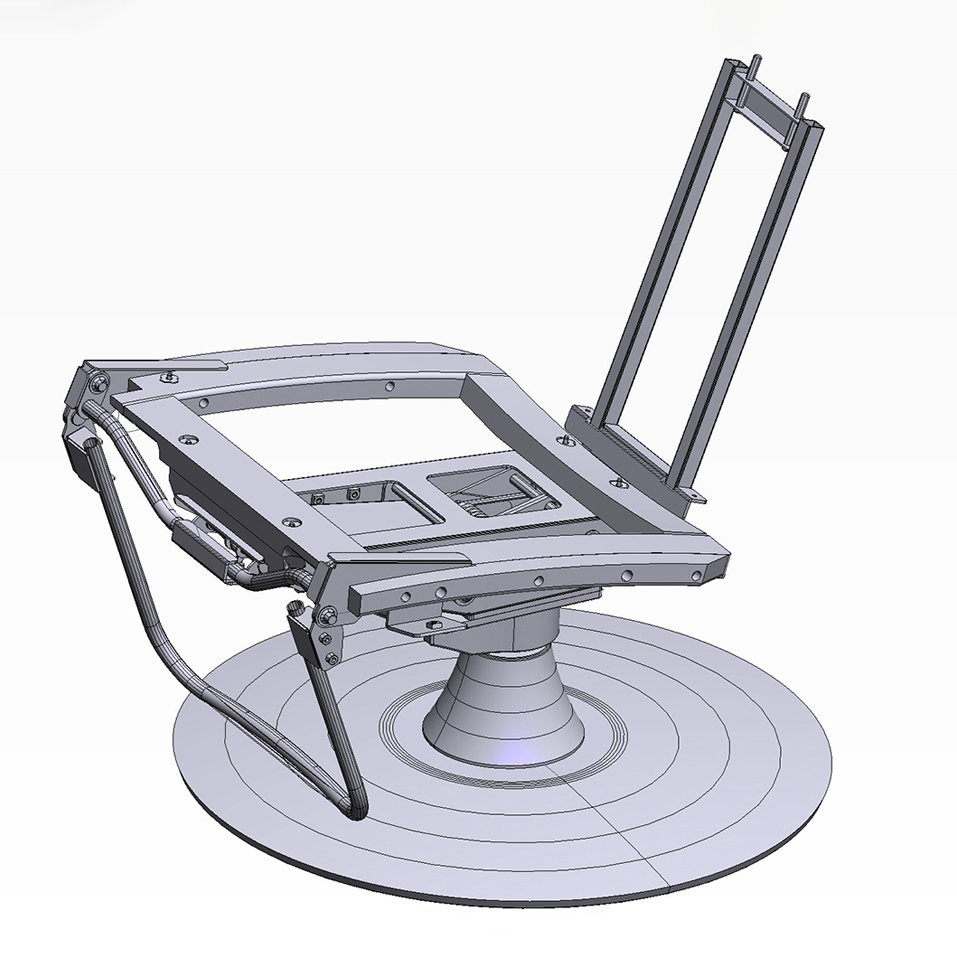

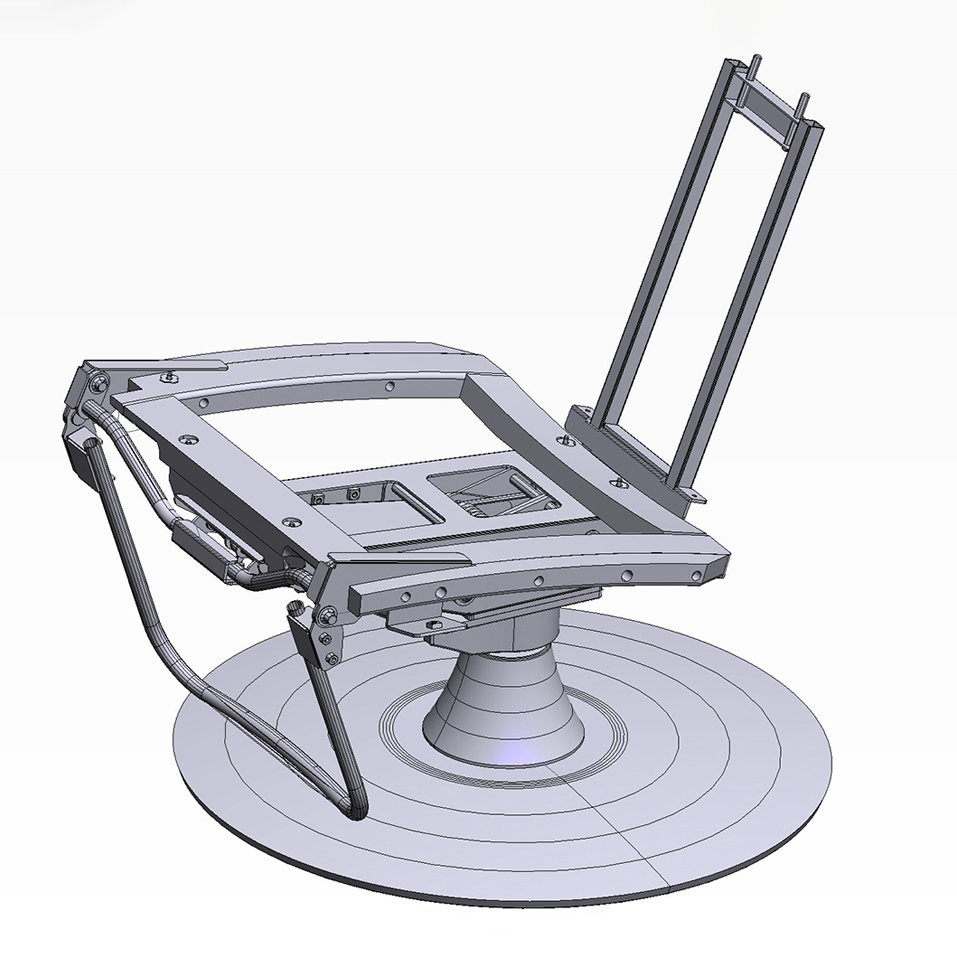

This was the first model of the recliner mechanism. We aimed to create a mechanism that, while interlinking the footrest with the movement of the backrest and incorporating a round function, could also accommodate various sizes and designs. The mechanism had a narrow width, and the foot area used flat metal, resulting in a design significantly different from today’s models.

We began to feel discomfort as the reclining angle and the speed at which the back tilts differed from our expectations, prompting us to pursue improvements in the reclining operation. Seventeen employees of varying genders and body types sat in the recliner and raised issues such as the instability of the reclining function, dissatisfaction with the angle, and the speed being too fast. Additionally, several major challenges arose, such as interference between parts and structures, and the protrusion of the mechanism.

This was the first model of the recliner mechanism. We aimed to create a mechanism that, while interlinking the footrest with the movement of the backrest and incorporating a round function, could also accommodate various sizes and designs. The mechanism had a narrow width, and the foot area used flat metal, resulting in a design significantly different from today’s models.

We began to feel discomfort as the reclining angle and the speed at which the back tilts differed from our expectations, prompting us to pursue improvements in the reclining operation. Seventeen employees of varying genders and body types sat in the recliner and raised issues such as the instability of the reclining function, dissatisfaction with the angle, and the speed being too fast. Additionally, several major challenges arose, such as interference between parts and structures, and the protrusion of the mechanism.

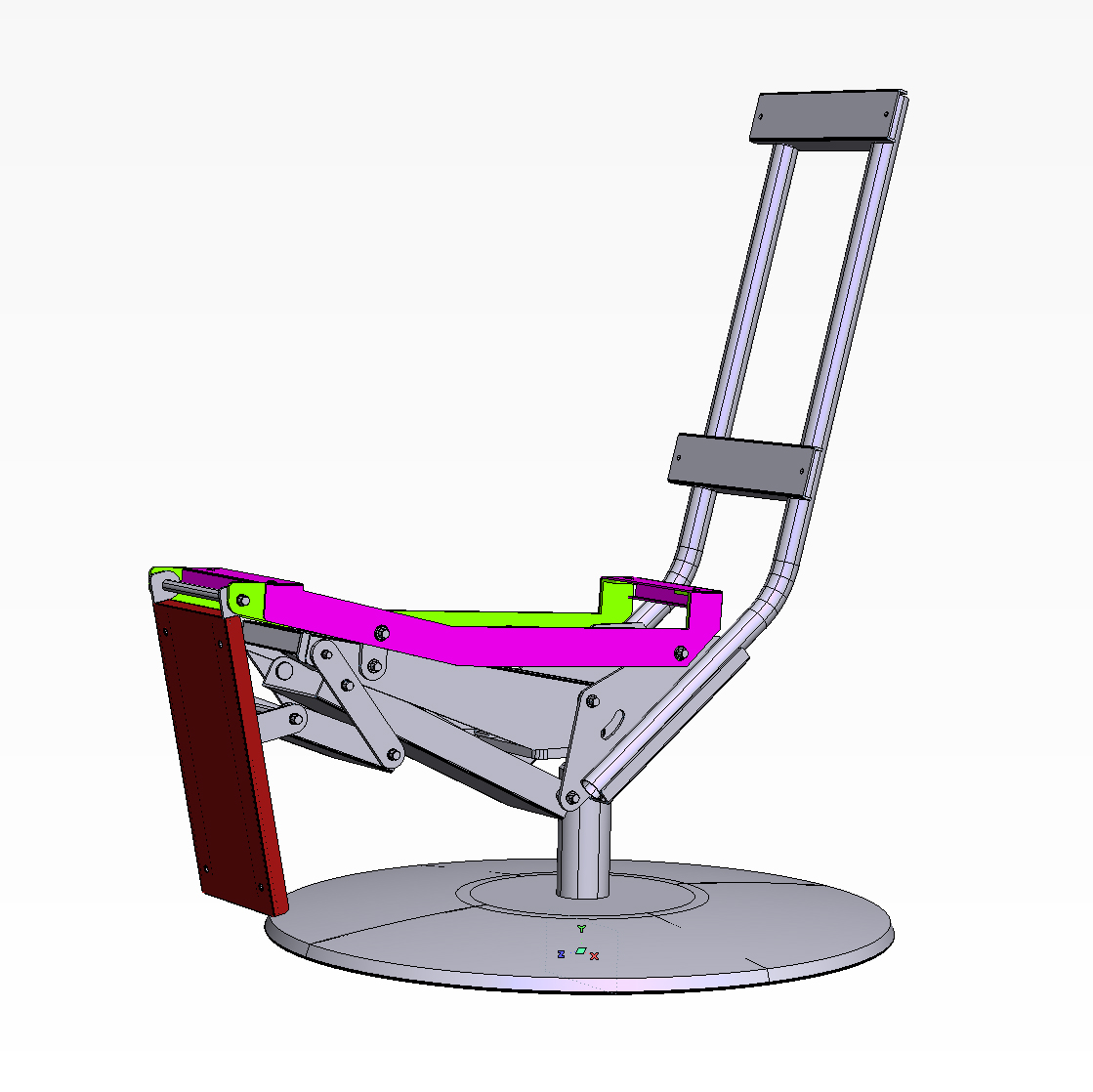

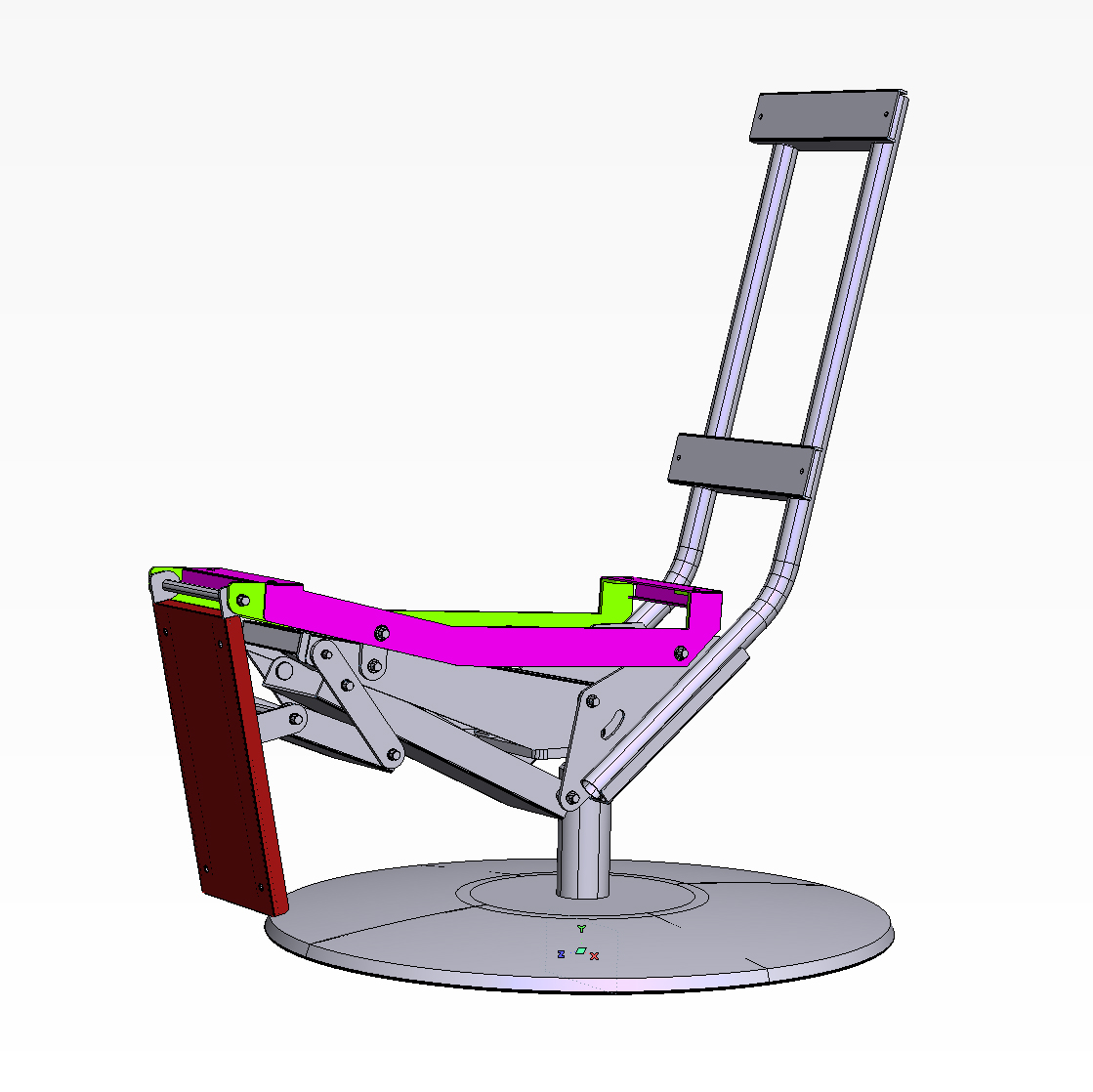

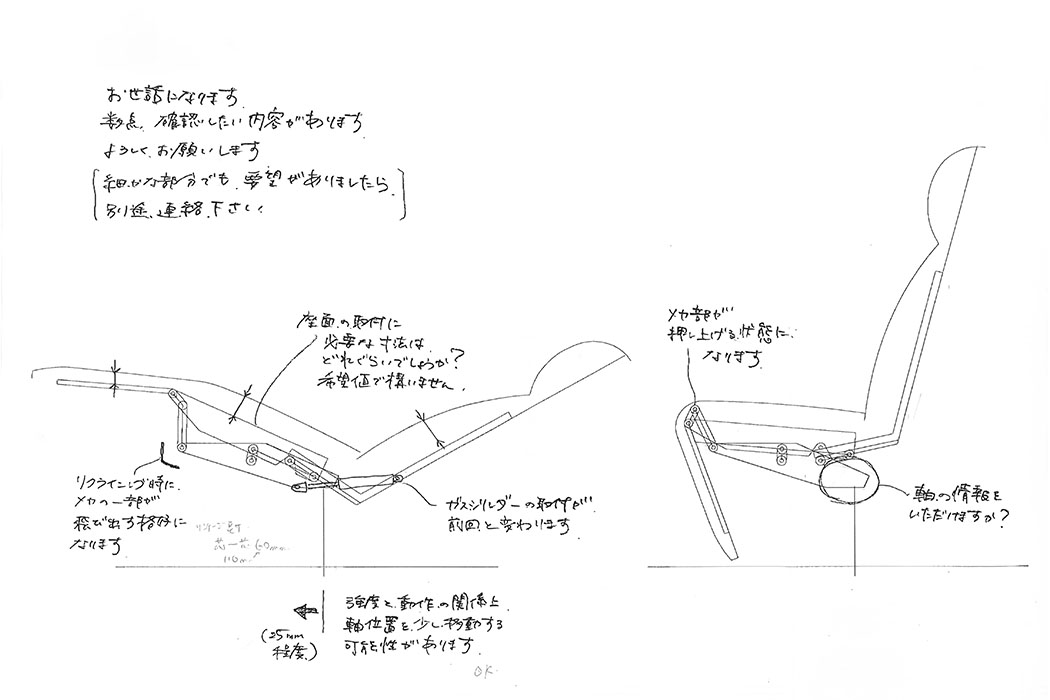

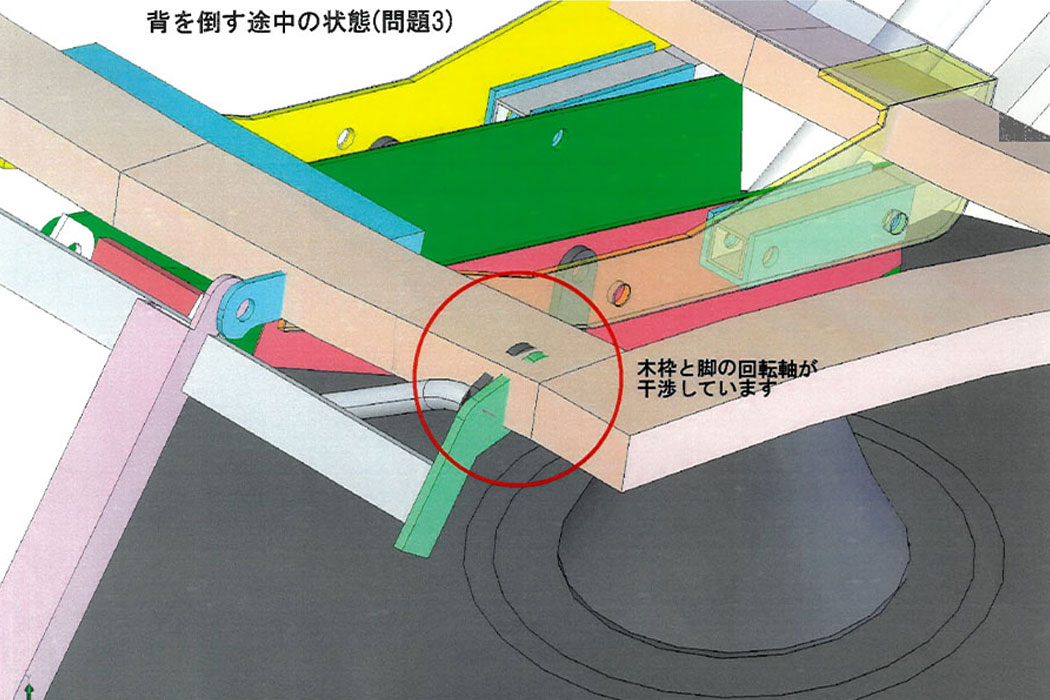

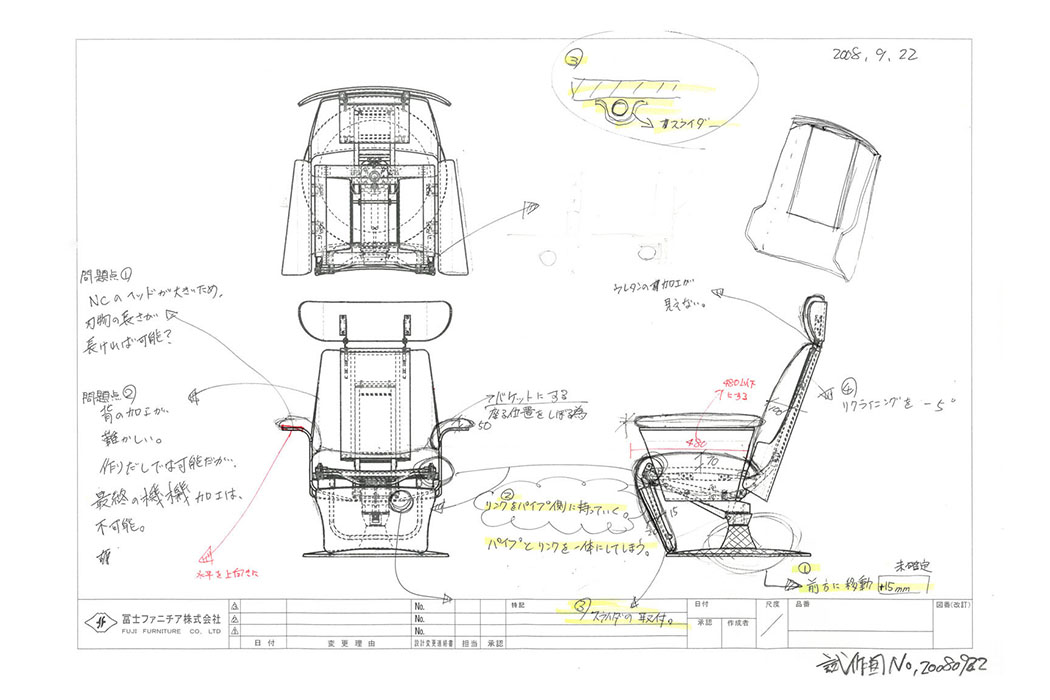

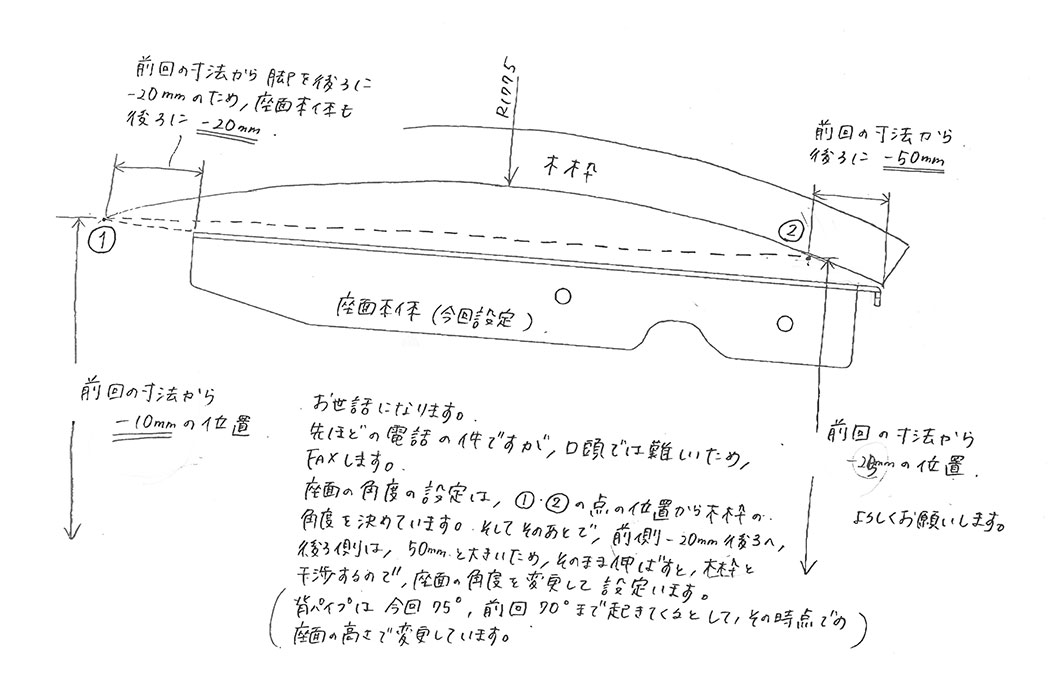

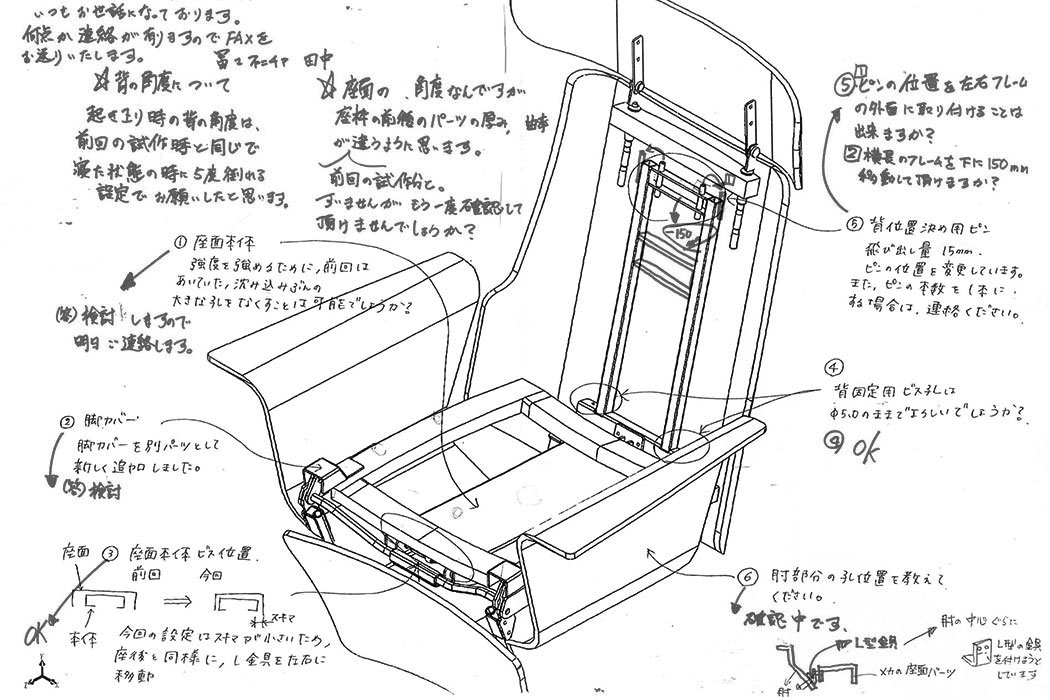

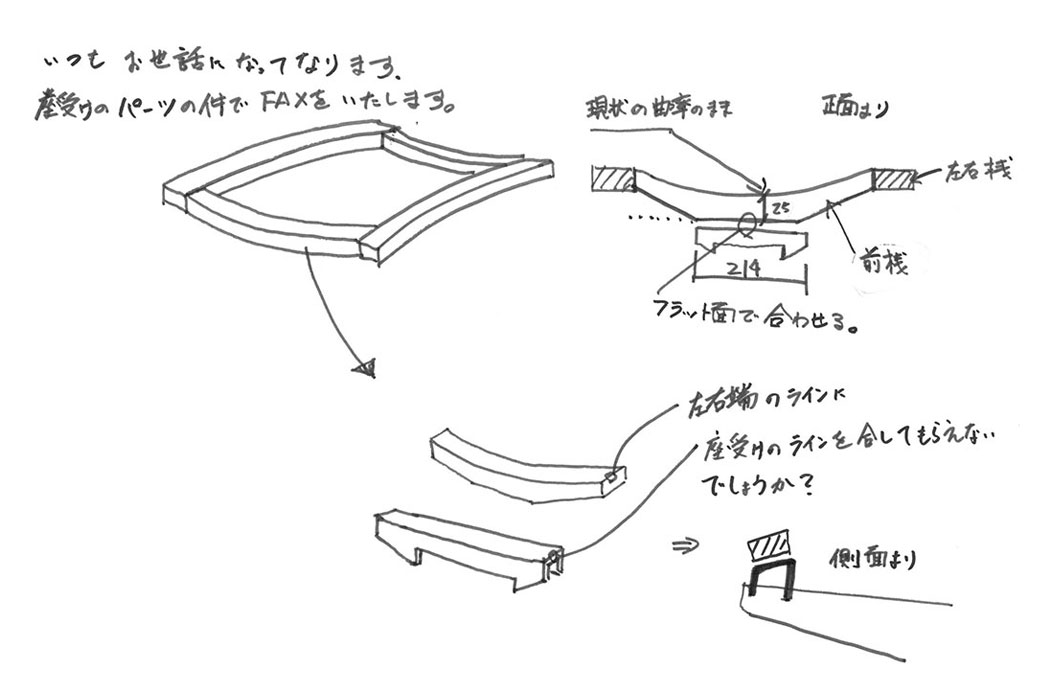

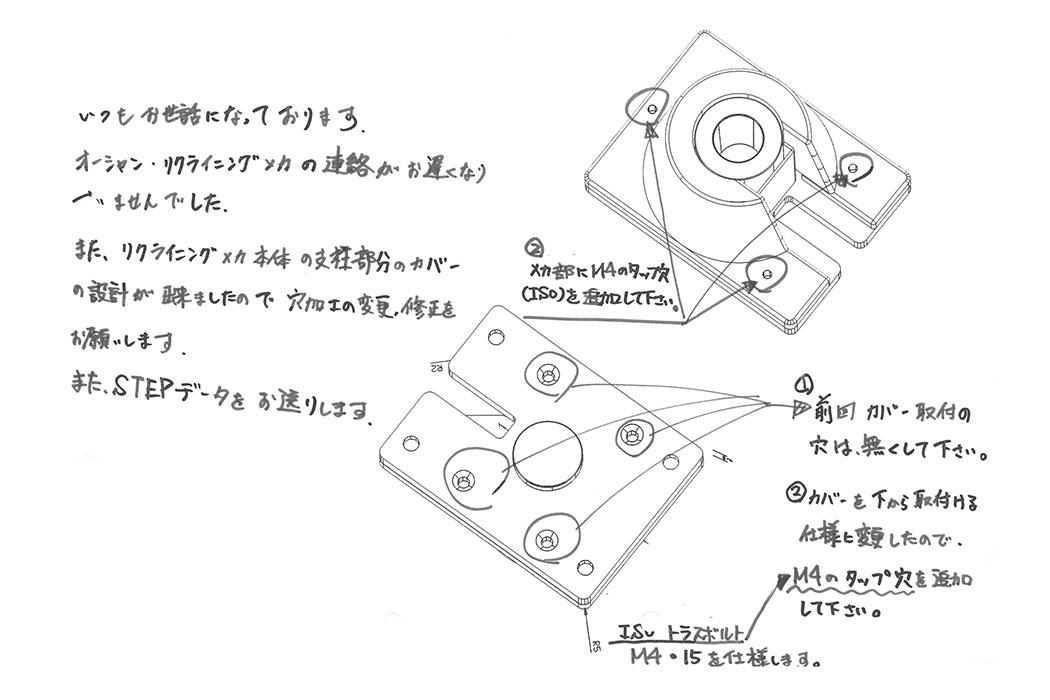

Protrusion issue of the mechanism and pushing up of the mechanism identified.

Interference issue between the wooden frame and the rotation axis identified.

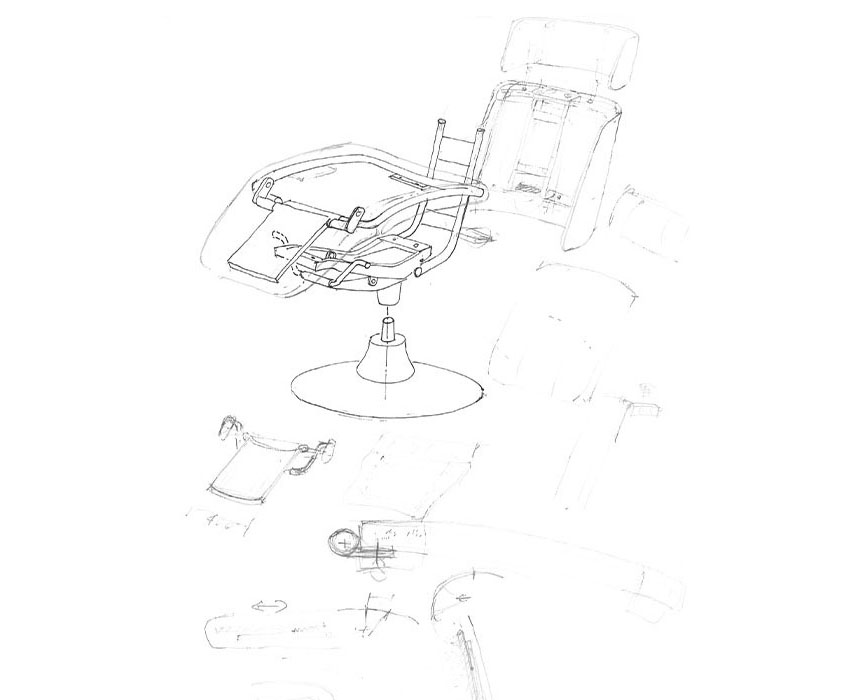

Structural assumptions from the state of the mechanism to the finished furniture.

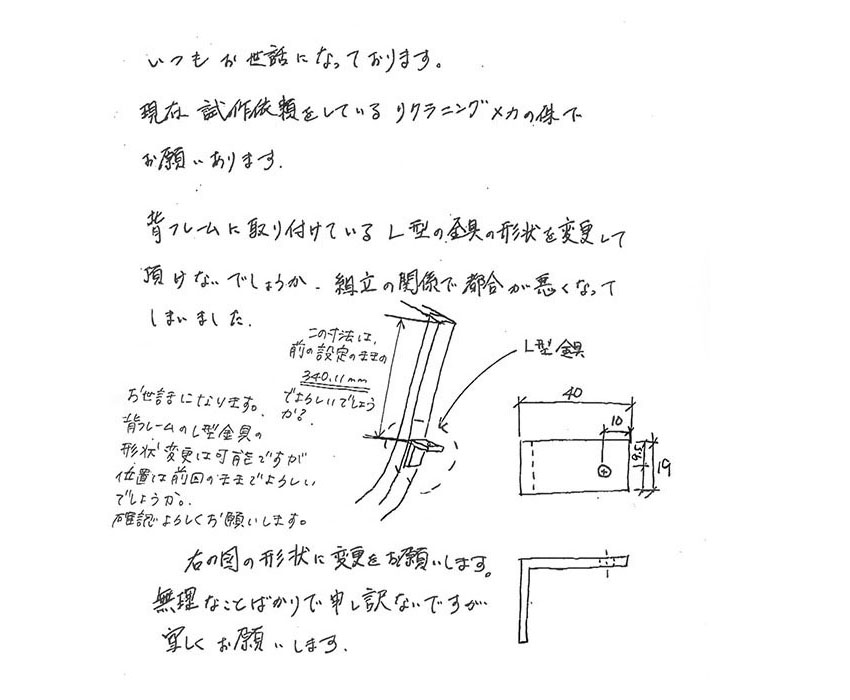

Request to change the shape of the L-shaped metal fittings.

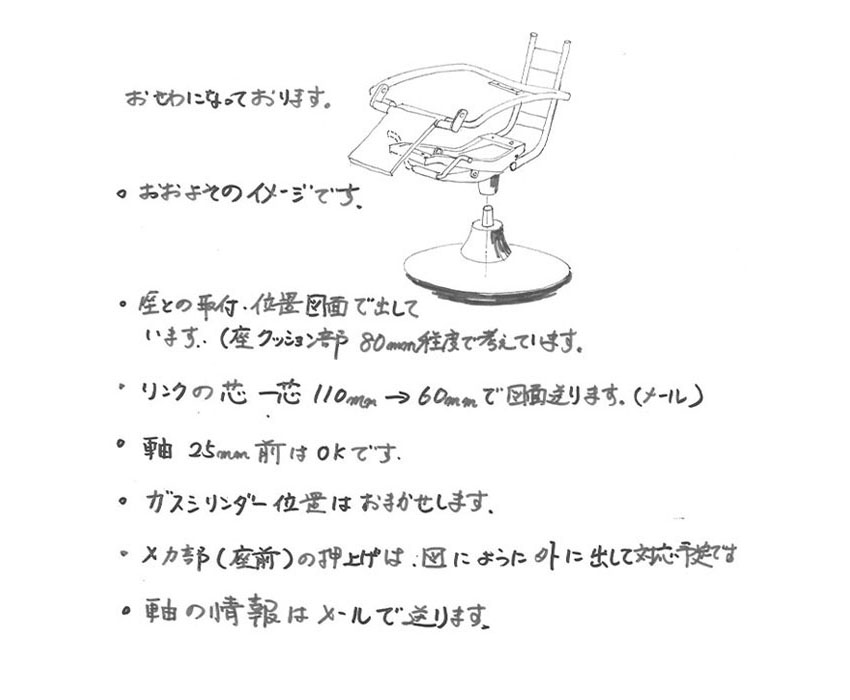

Responded to questions using hand-drawn diagrams.

We made improvements to the structure involved in the operation of the foot mechanism, considering safety aspects. Aiming to make the reclining operation easier, we installed gas cylinders in the back. On the other hand, there were concerns about the strength on the sides of the main basic structure of the seating area due to the thinness of the plates used.

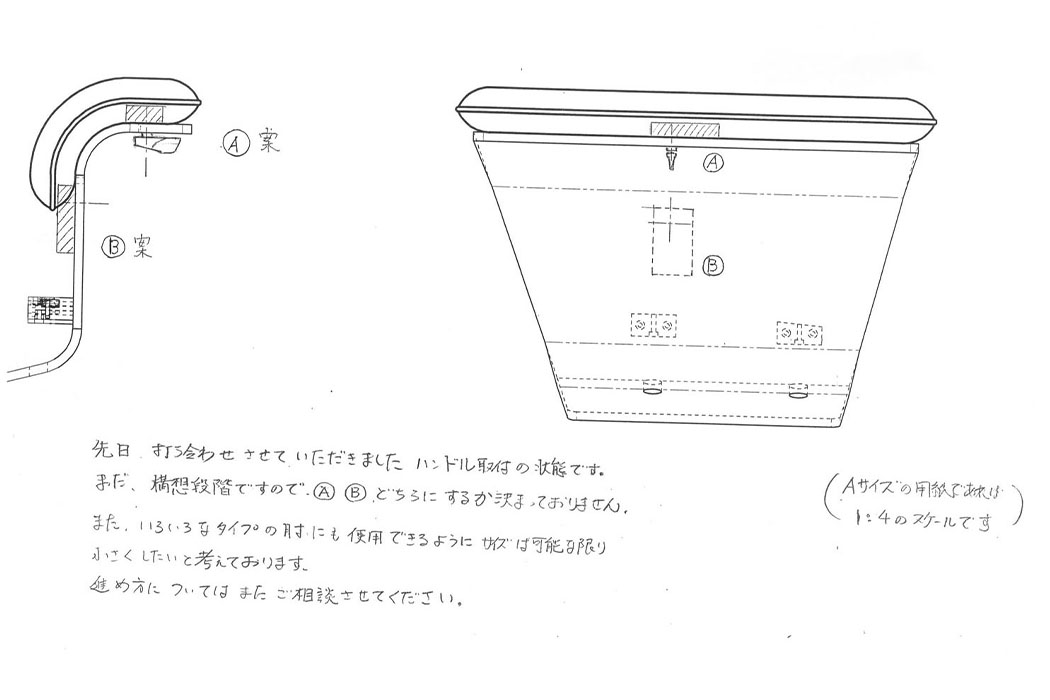

The number of detailed examination items increased, such as the position of the metal fittings and the shape of parts. New production also began for the handle lever used to operate the reclining function, striving to make it as simple and compact as possible while aligning with the recliner’s design. The positional relationship of the pivot points for the mechanisms of the back and seat sections was decided, adjusting the instability of the reclining and the speed of reclining that had been identified as issues. This positional relationship of the pivot points became the foundation for the later Prototype Model.

We organized the challenges in manufacturing and the detailed examination items.

Mock-up with urethane applied. The cushion is thin, and the operating lever is exposed.

Confirmed the positional relationship of the pivot points for the mechanisms of the back and seat sections using models.

Conceptual ideas regarding the handle lever.

By relocating the gas cylinders that were mounted on the back to the seating area to consider assembly, and by covering the surface with U-shaped covers, we improved the strength of the main mechanism. To enhance manufacturing operability, we modified the design to allow the foot mechanism and the seat frame to be attached. However, a new issue arose where the foot’s fixing metal fittings interfered with the urethane.

As we refined the details, problems such as interference between parts and protrusion arose, leading to numerous meticulous communications with Ichinotsubo Seisakusho. We created mock-ups close to the final form and addressed issues like wobbling, noise, and seating comfort.

By relocating the gas cylinders that were mounted on the back to the seating area to consider assembly, and by covering the surface with U-shaped covers, we improved the strength of the main mechanism. To enhance manufacturing operability, we modified the design to allow the foot mechanism and the seat frame to be attached. However, a new issue arose where the foot’s fixing metal fittings interfered with the urethane.

As we refined the details, problems such as interference between parts and protrusion arose, leading to numerous meticulous communications with Ichinotsubo Seisakusho. We created mock-ups close to the final form and addressed issues like wobbling, noise, and seating comfort.

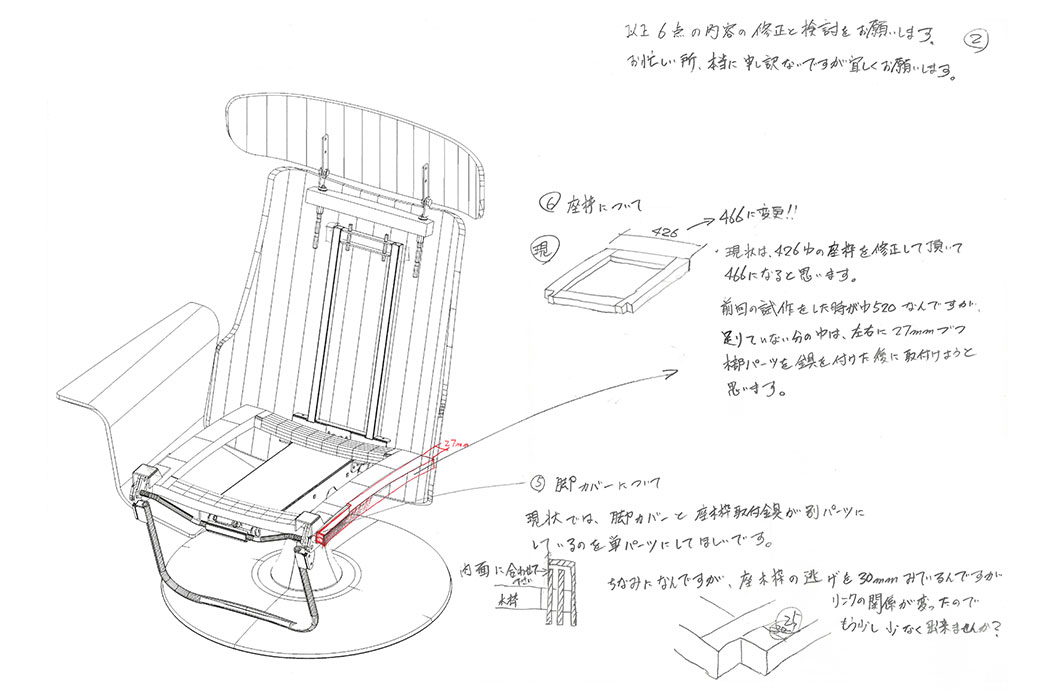

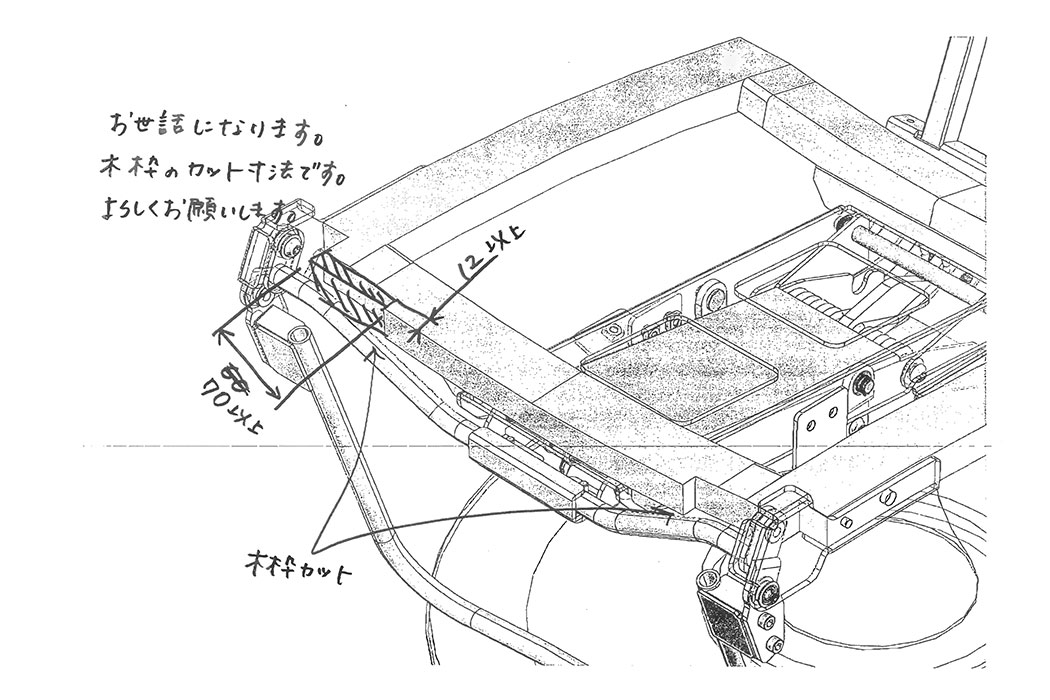

Impact of dimensional changes.

Confirmation and responses to detailed aspects.

Request to change the seat frame and leg covers.

Request to change the seating components.

Mock-up with upholstery and molded frames attached. The cushion lacks volume and has no distinct differentiation.

Request to change the dimensions of the wooden frame.

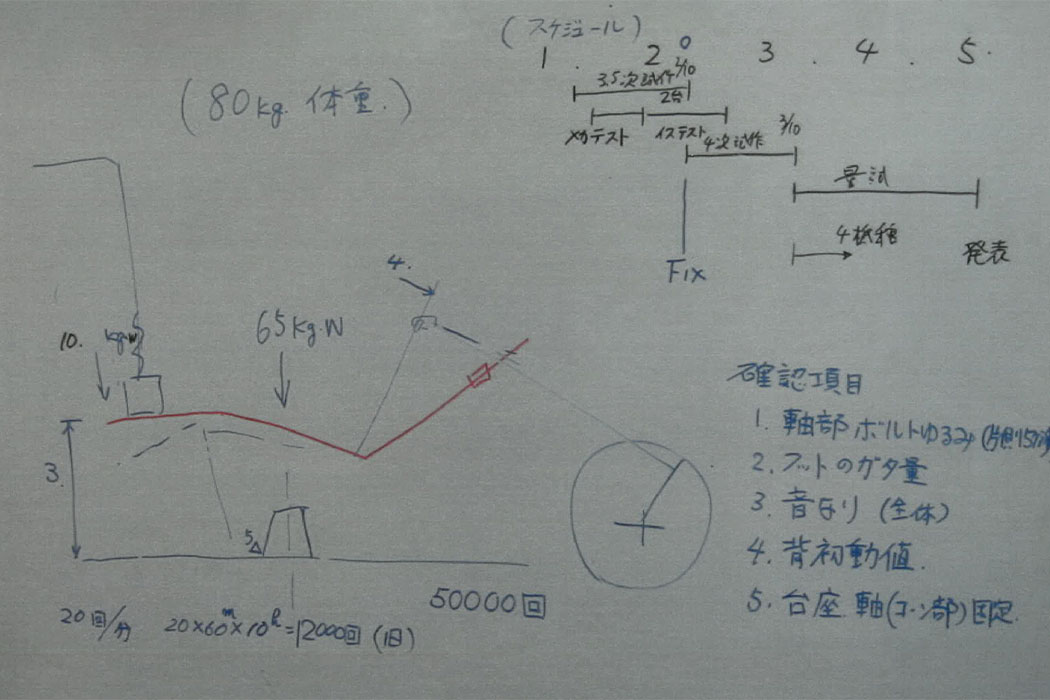

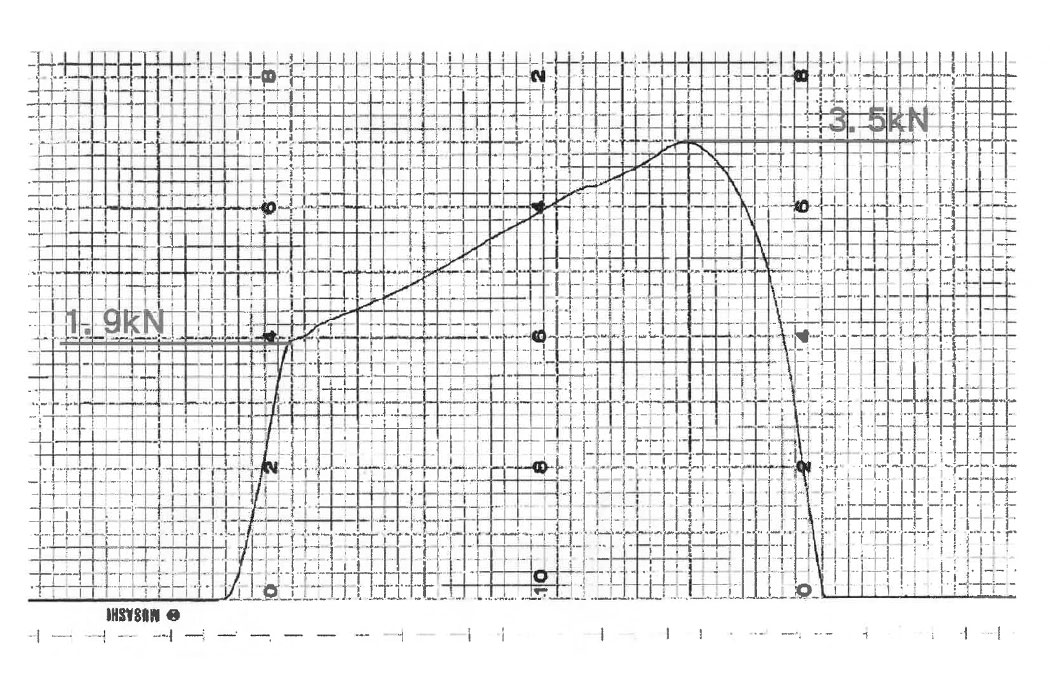

Plan for strength testing conducted at FUJI FURNITURE. Confirmed whether the recliner can withstand 50,000 reclining cycles under a load of 65 kgw applied to the seat.

Scenes of strength testing conducted at FUJI FURNITURE.

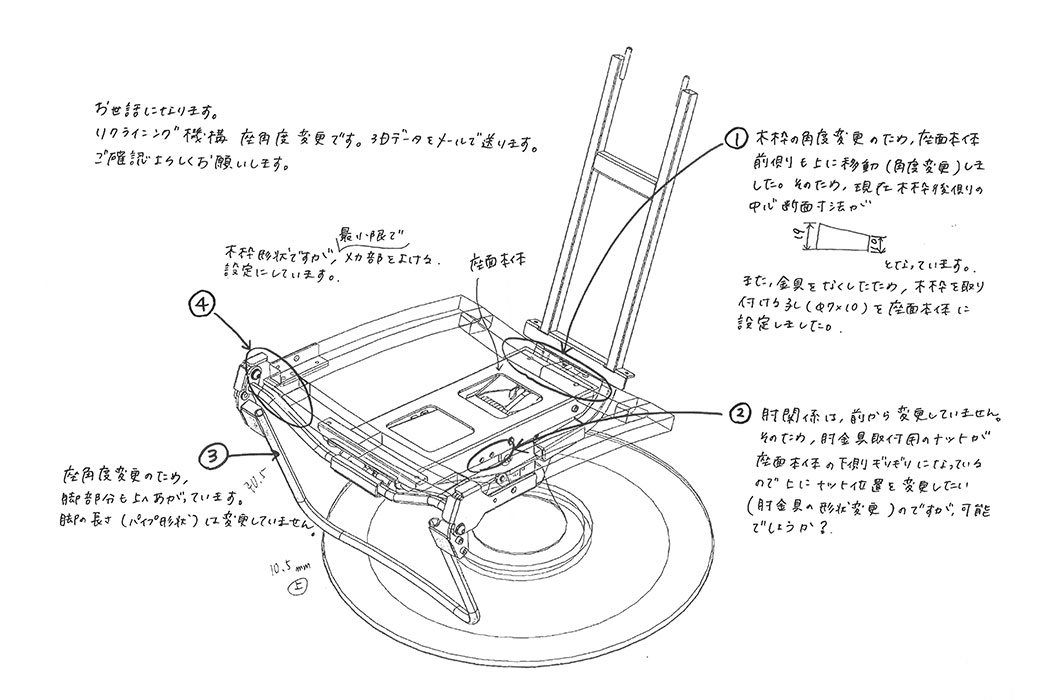

Although the introduction of covers at the attachment points of the foot mechanism and seat frame improved interference with the urethane, the shape caused the covers to protrude from the seat frame, leaving a sense of discomfort when touched. Aiming for further improvement in strength and durability, we modified all structures related to the seat’s movement from flat plates to U-shaped designs. To make the headrest movable, which was fixed up to the 3rd Prototype Model, we changed the shape of the upper back part.

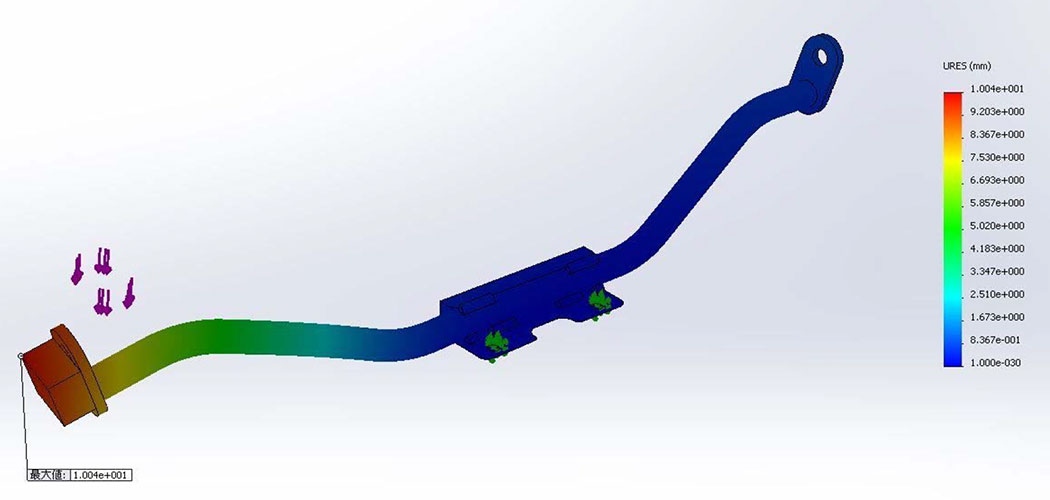

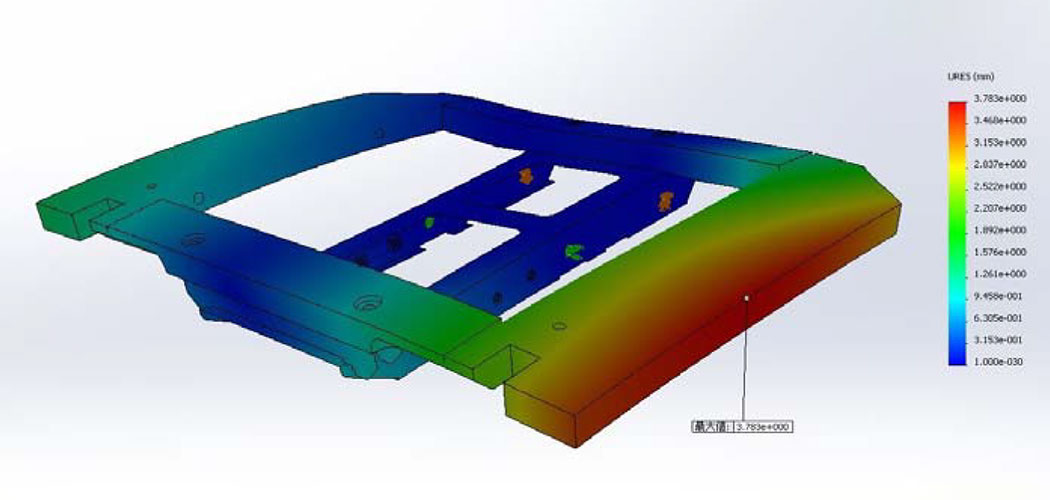

At Ichinotsubo Seisakusho, multiple durability tests were conducted on the mechanism, analyzing displacement under load. By not only demonstrating the relative strength of the mechanism but also the strength of each part, we achieved more substantiated results.

Design changes to allow adjustments of the seat angle.

Changed specifications for the mechanism support covers.

Conducted mechanism strength testing at Ichinotsubo Seisakusho. Applied load to the foot section to confirm the impact on the seating section.

Conducted mechanism strength testing at Ichinotsubo Seisakusho. Applied load to the seating section until deformation.

Strength analysis of the mechanism rods. Confirmed displacement when load is applied to the left side.

Strength analysis of the mechanism seat section. Confirmed displacement when load is applied to the right side.

The continually improved foot mechanism resolved the discomfort felt when touching by flattening the connection with the seat frame. By lowering the height of the back section, the efficiency of assembly operations during manufacturing was enhanced. By installing springs to assist reclining and performing final adjustments by hollowing out the U-shaped covers for weight reduction, a mechanism that achieved both lightweight and durability was completed.

FUJI FURNITURE obtained a patent to protect this original mechanism and its products and technologies. They will continue to protect their products and technologies while aiming for further development.

■Patent Number: 5306848

■Patent Registration Date: July 5, 2013

■Title of Invention: Chair

■Patent Holder: Fuji Furniture Co., Ltd.

The continually improved foot mechanism resolved the discomfort felt when touching by flattening the connection with the seat frame. By lowering the height of the back section, the efficiency of assembly operations during manufacturing was enhanced. By installing springs to assist reclining and performing final adjustments by hollowing out the U-shaped covers for weight reduction, a mechanism that achieved both lightweight and durability was completed.

FUJI FURNITURE obtained a patent to protect this original mechanism and its products and technologies. They will continue to protect their products and technologies while aiming for further development.

■Patent Number: 5306848

■Patent Registration Date: July 5, 2013

■Title of Invention: Chair

■Patent Holder: Fuji Furniture Co., Ltd.

FUJI FURNITURE products, including our original mechanisms and recliners, are produced domestically, allowing us to swiftly address any issues that may arise. Unlike overseas products, which can incur time and costs for ordering and support, our products do not have such disadvantages. Being able to provide superior aftercare to our customers is a significant feature of our original mechanisms and FUJI FURNITURE products.

We also began exporting to South Korea in 2017, and to China and Taiwan in 2020. Our luxury designs, smooth operational feel, and assured strength and safety have been highly valued and well-received.

Through the development of the mechanism, the recliner is equipped with reclining functionality, a round function, and headrest adjustment capabilities, enhancing satisfaction in the office environment.

Reclining is achieved solely through body weight movement, and using the lever at hand, you can lock it at your preferred angle, allowing you to adjust to a comfortably intuitive position. As the back tilts, the footrest rises in tandem, and the angle of the headrest can also be finely adjusted. Not only can you relax in a full-flat posture from head to toes, but with the 360-degree rotating round function, you can sit from any direction. This makes it easy to turn towards someone who speaks to you while you are working.

The cushion, which supports a leaning body, is thick and shaped to follow the contours of the body. The headrest features a curved design that gently cradles the head. The details where the wooden parts seamlessly adhere to the cushion create a beautiful aesthetic.

A large curved surface, boldly utilizing molded plywood, accentuates the beauty of the wood grain. After bending the molded plywood, the wooden parts are processed using an NC (Numerical Control) machine that cuts them based on programmed inputs. This ensures that the curves of the molded plywood remain intact, resulting in a beautiful finish visible from any of the 360 degrees.

Inside the cushion, urethane tailored to each section is used. The seat incorporates high-density, durable molded urethane. The appearance offers a firm feel, while the seating comfort is spacious. You can enjoy a high-class experience.

The foot section resembles a dolphin’s head, and the head section evokes a dolphin’s tail fin, featuring a design that makes it look like a dolphin is swimming freely. The fully upholstered design tightens the overall appearance, accentuating the beauty of the silhouette.

Designed with a relatively standard size, the Dolphin emphasizes a snug fit when seated through its thick cushions and a design that slopes towards the back of the seat, creating a sense of security that makes you want to sit for extended periods.

Rounded armrests and curved stitching that connects to the headrest are incorporated throughout the design, creating a cohesive overall appearance and providing visually pleasing comfort.

The smooth lines that seamlessly connect from the head to the toes are captivating, and the unified form visible from any angle is born from meticulous attention to detail. It is a recliner that offers new discoveries each time you sit.

The connections between parts such as the back and armrests, the integration between the cushions and molded plywood, and the soft, curved swell of the cushions all reflect a design conscious of every contour line, creating a beautiful aesthetic.

The molded plywood that adheres closely to the cushions has its thick sections rounded and chamfered. This extra touch significantly influences the impression when touched casually, providing a tactile feel that makes you want to keep touching it.

出展商品

Hammerhead リクライニングチェア P04500 A BP Triangle 0192

Dolphin リクライニングチェア P04520 A BP Triangle 0152

Kangu リクライニングチェア P04940 A BP Triangle 0122

詳細は各Productsページをご確認ください。

Hammerhead Productsページ

Dolphin Productsページ

Kangu Productsページ

*塗装色の品番は以下の通りです。

ブラック:BP(オーク)

*張地の品番は以下の通りです。

Special Fabric “Kvadrat” Triangle 0192 / 0152 / 0122

カタログやHPに未掲載の特別張地です。

張り地や価格につきましては Contactフォーム よりお問い合わせください。