We, Fuji Furniture, have been engaged in “Kaizen” (improvement) activities since 2010.

This initiative was triggered by a “crisis” that came to us. Since our establishment in 1959, we have been manufacturing various products to meet the changing needs of the times as a furniture manufacturer, but soon after the beginning of the 2000s, we hit a wall: products were not selling well and the production efficiency of the factory was declining.

Let’s go back to 1989, the first year of the Heisei era. At that time, we were living in a society of “mass production and mass consumption.

The most popular product was the L2610 parlor set, and if you produced a large quantity of a hot-selling product, orders would naturally come in and it would sell. If you lined up popular products at furniture stores, they would sell as many as you lined up. Such was the era.

However, from the late 1990s to the 2000s, the market began to show signs of change. Orders for previously popular products decreased, and furniture stores began to notice unsold items. Sensing such changes in consumer needs, we proceeded to develop many new products.

However, our desire to “expand our product lineup so that more and more customers can choose our furniture! As a result, our production efficiency deteriorated rapidly.

In order to fundamentally change our production methods, we started “improvement activities” to introduce the “Toyota Production System” in November 2010. We are determined to identify the wastage that is hidden in manufacturing, and to make sure that we produce what is really needed now, just in time. We have decided to shift from prospective production to full order production.

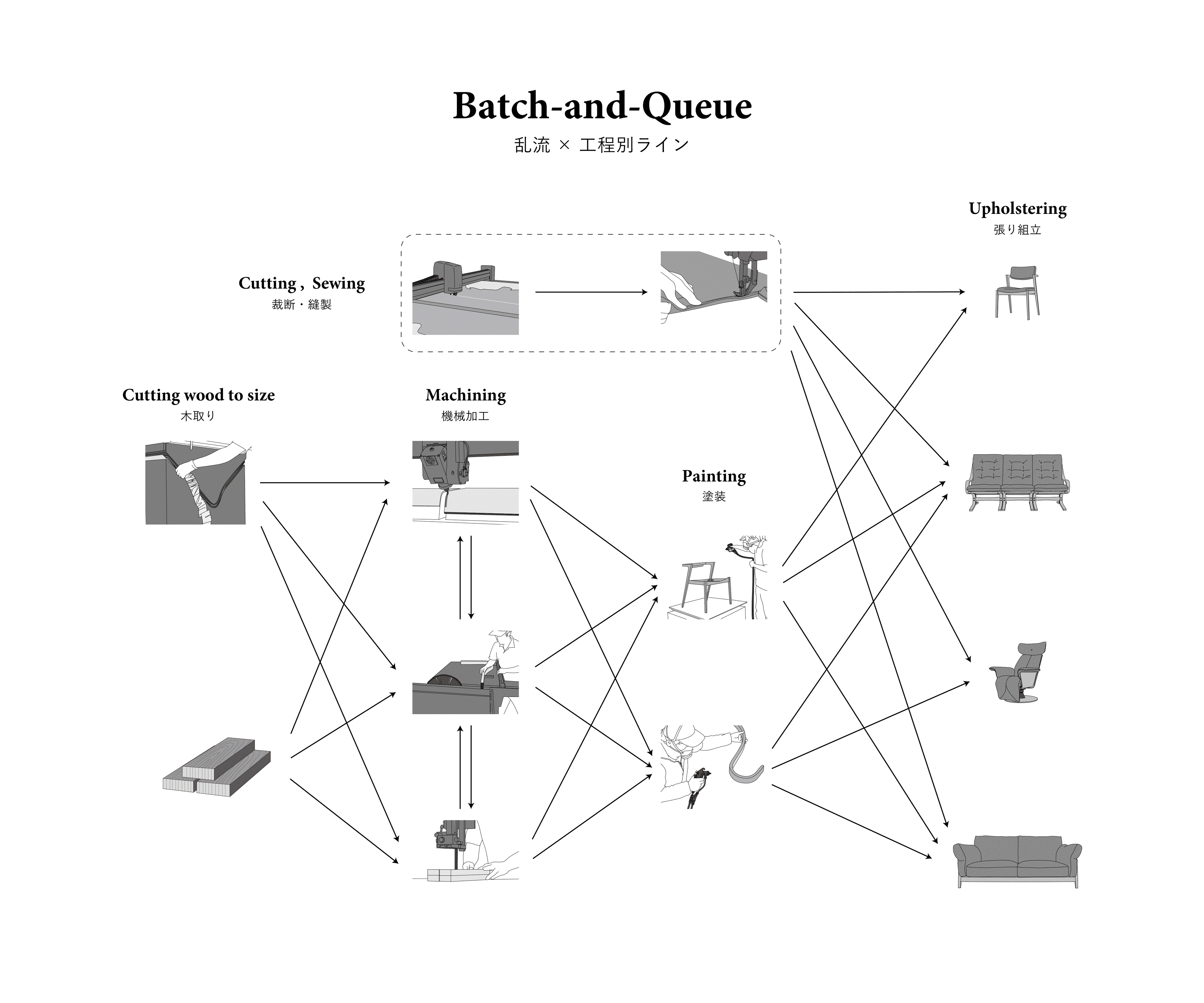

The production system at that time was to divide the entire factory into separate processes. In this case, each process tried to produce parts in bulk, and work-in-process (parts in the process of being processed) would be held up between processes. This means that the necessary parts cannot be supplied just in time.

First of all, in order to improve the production flow in the factory, we changed to a “single-unit flow” system where products are made one at a time.

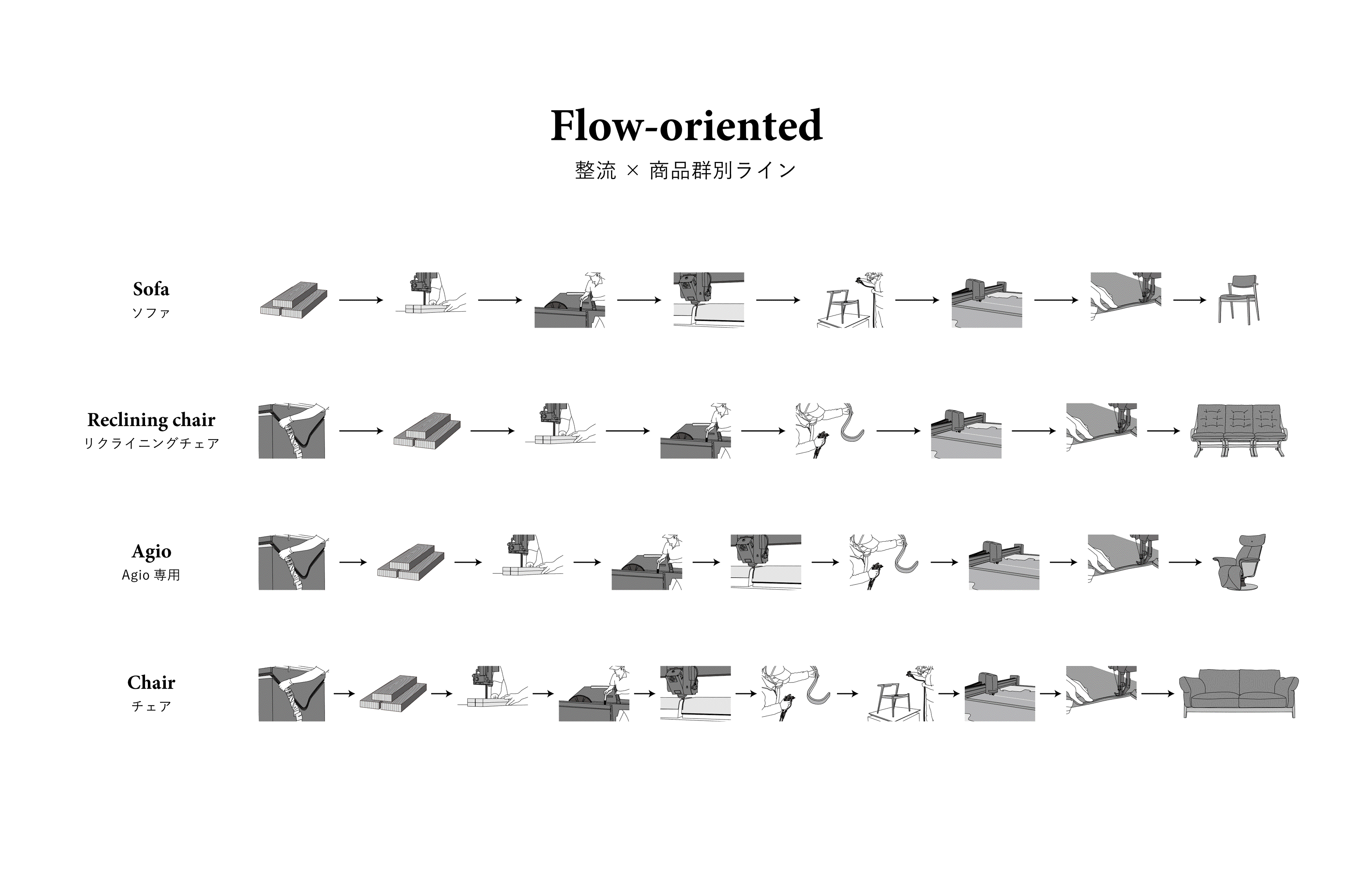

Then, in order to further improve the efficiency of the “one-unit flow,” we created several smaller lines for different product counties.

In order to further increase the efficiency of the “single-unit flow,” we created several smaller production lines for different products, such as a dining chair production line, a sofa production line, and a table production line. The system can be changed flexibly according to the order situation from customers.

Then, in order to further improve the efficiency of the “one-unit flow,” we created several smaller lines for different product counties.

In order to further increase the efficiency of the “single-unit flow,” we created several smaller production lines for different products, such as a dining chair production line, a sofa production line, and a table production line. The system can be changed flexibly according to the order situation from customers.

For example, a sofa takes about 10 times as long to produce as a dining chair. Production on the same line will result in variations in work.

The product group-based line has the advantage that products with similar composition can be produced on the same line, which improves work efficiency.

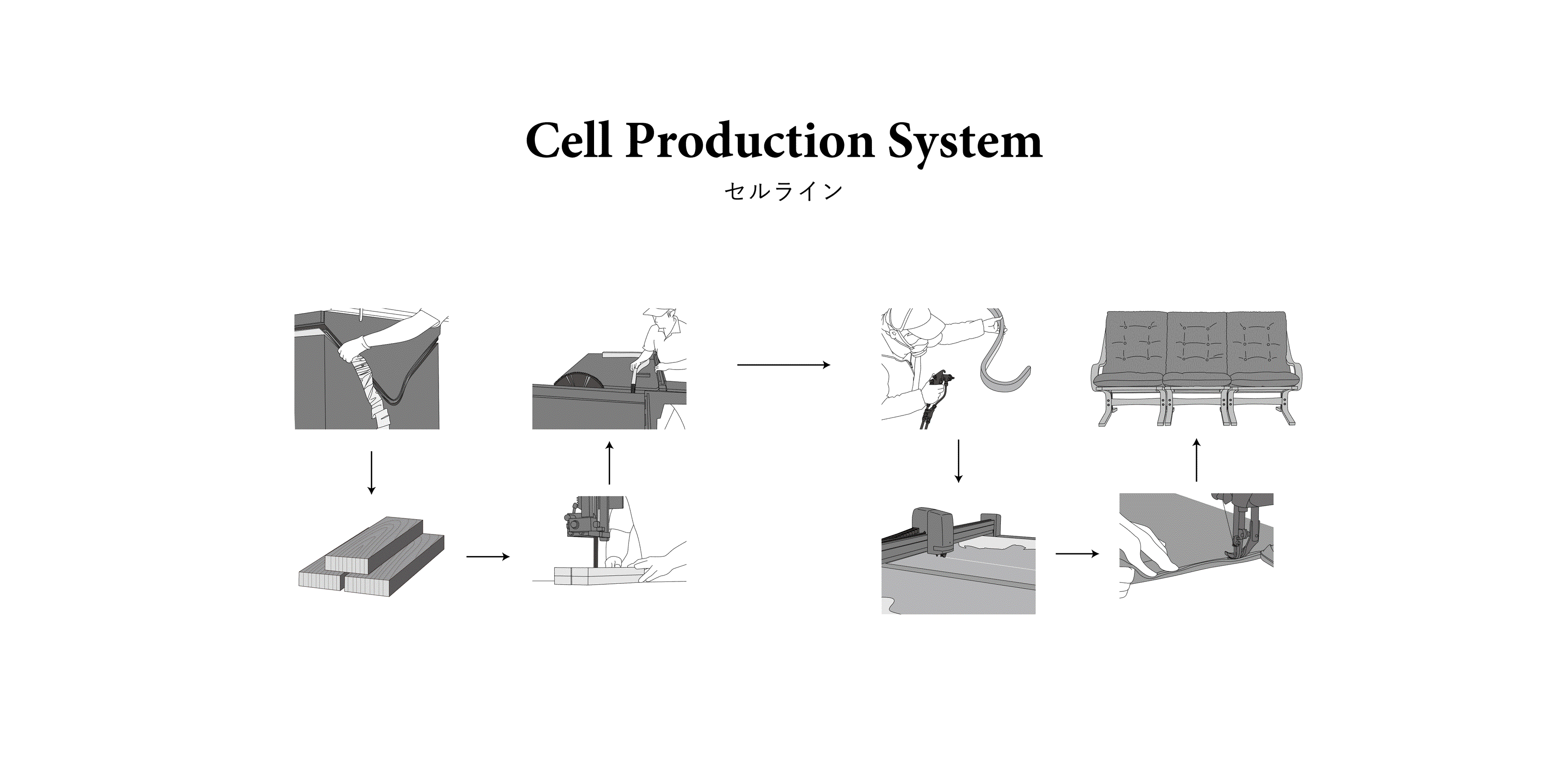

In order to create an environment where we can share the progress of each other, we have introduced the cell line method, where processes are arranged in a circle with a small team. By helping each other with bottleneck processes, we are able to reduce work-in-process inventory and shorten manufacturing lead time.

We also focused on cycle time management of the production line (i.e., management of the target time to complete a unit of product) and promotion of multi-skilled workers so that one person can work on multiple processes.

In this way, we have been able to realize a production system that enables efficient production of a wide variety of products in small quantities.

The “improvement activities” fundamentally disrupted the production system of the factory, which had remained largely unchanged for decades.

The company was in turmoil for a while, with disagreements and strong opposition.

However, because of our passion for furniture that has been handed down since the beginning of the company, we were able to continue our activities without stopping, believing that we would be able to improve the production system.

Our furniture is not mass-produced, but completely made-to-order, made just for you. We produce furniture with the wood species, paint color, and upholstery material of the customer’s choice.

Improvement activities are necessary for us to deliver ideal furniture to as many customers as possible, and for our own growth.

We want our customers to experience the joy of choosing a product that they themselves have selected and that is being created for them from scratch.

We will continue our “Kaizen” activities to become a brand that continues to change with the times, without wasting resources such as materials, human resources, and time.