At Fuji Furniture, we are constantly thinking about how we can pass on our skills.

It is not uncommon in the manufacturing industry for masters to tell their apprentices to “learn by watching” or “steal skills”.

Since it is difficult to quantify and verbalize craftsmanship and highly specialized knowledge, the question of how to pass it on is one we have been asking ourselves for years. This is a challenge that we have been facing for many years.

In the past, when we had a mass production system, the same products were made every day on the production line, and we could naturally acquire skills by performing daily tasks. After the complete made-to-order production system was introduced, the daily work became more diversified due to the diversification of products, and it became necessary to provide special opportunities and an environment to pursue a single technique.

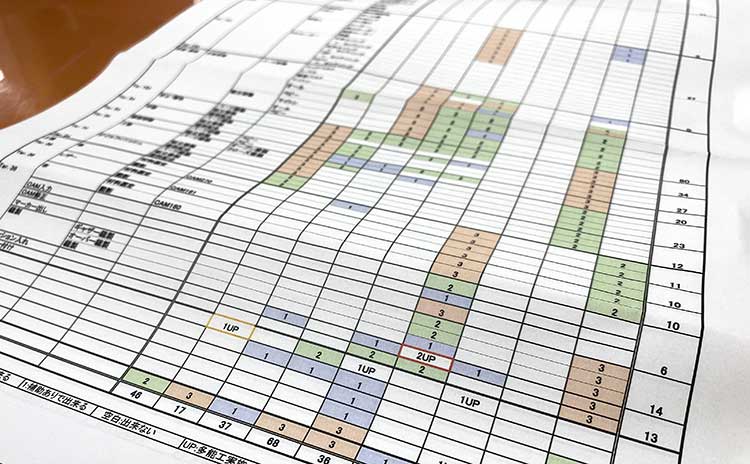

まずは、現状の保有技能を可視化するために、スキルマップを作成するところから始まりました。各工程の作業を「教えることができる」「補助があればできる」など、人ごと・工程ごとに管理することで、教育計画が立てやすくなります。

The first step was to create a skill map in order to visualize the current skills held. By managing the tasks of each process by person and process, such as “can be taught” or “can be done with assistance,” it becomes easier to make training plans. In addition, creating “important points of work” that summarize the important parts of the work content will help the skills to be established.

Education is conducted not only during daily work, but also during environmental maintenance, which is one of the company’s initiatives.

For example, for many years there was only one craftsman in the company who could hand-apply veneer, but with one-on-one guidance from the craftsman, younger employees can now do the less difficult hand-application work.

It took four to five months from the start of the instruction to the point where they were allowed to work on the actual product, but the joy and sense of accomplishment when they applied the veneer to the product for the first time greatly increased the motivation of the young employees.

Due to the advanced technology, it is not possible to make a manual. The craftsmen show their own work and explain it carefully, and then let them actually do the work. Even if they fail, they persistently teach. They answer questions thoroughly.

I want to take the time to teach them so that they will be able to hand over their own signboards,” said the craftsman.

We have established a system to support the acquisition of qualifications such as the National Trade Skills Test, first-class architect, interior coordinator, and interior planner, and provide guidance for taking these exams. We also believe that it is necessary to pass on skills not only in manufacturing, but also in development and clerical departments, and we hold study sessions where veteran engineers gather with younger employees.

We want to continue to produce ideal furniture for our customers by passing on the furniture-making skills we have cultivated over the years since our founding. In addition to this desire, we will create an environment in which the eggs of future craftsmen working at Fuji Furniture can continue to hone their skills with pride.