CSR

Based on our mission of “Make each one of you as the “Protagonists of Life” from the new value created by “Creative Destruction”, Fuji Furniture believes that CSR activities should aim to continue efforts to make employees, customers, business partners, and local communities the “Protagonists of Life”.

We will create a workplace environment where employees can work with peace of mind.We will improve employee satisfaction by developing systems and personnel systems that increase employee motivation.

Our company puts safety first and continues to improve the safety of our plants. We also continue to improve our work environment.

Our company puts safety first and continues to improve the safety of our plants. We also continue to improve our work environment.

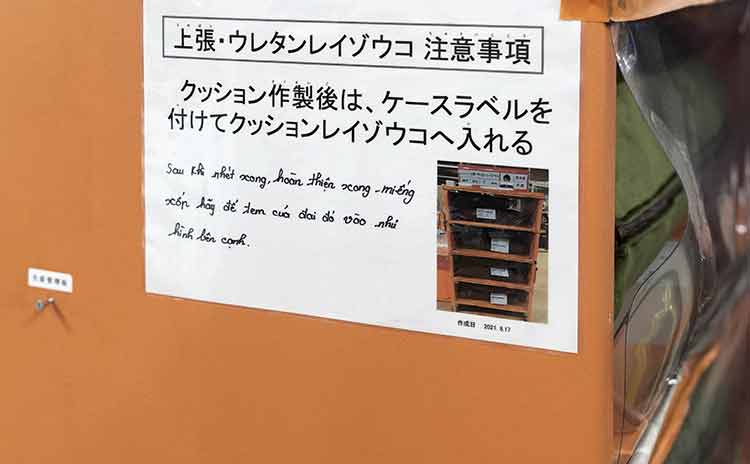

Our company strives to create a work environment in which people with diverse personalities can fully demonstrate their abilities.

Our company strives to create a work environment in which people with diverse personalities can fully demonstrate their abilities.

We are pleased to announce that we have been certified as one of the “Excellent Corporations for Health Management 2024” under the Certification System for Excellent Corporations for Health Management, promoted by the Ministry of Economy, Trade and Industry and the Japan Council on Health.

Initiated in 2017, this certification system aims to publicly recognize companies that prioritize employee health management from a managerial perspective and actively implement initiatives to enhance employee well-being.

Since 2010, we have continuously pursued “kaizen” improvement activities. Over the past decade, our “multi-skilled workforce” has evolved, enabling employees to handle multiple processes and support each other daily. This progress has not only ensured smooth production but also led to a significant reduction in overtime work, contributing to our recognition and certification.

We remain committed to valuing the health and safety of every employee as a crucial asset in our mission to manufacture products that satisfy our customers.

We are pleased to announce that we have been certified as one of the “Excellent Corporations for Health Management 2024” under the Certification System for Excellent Corporations for Health Management, promoted by the Ministry of Economy, Trade and Industry and the Japan Council on Health.

Initiated in 2017, this certification system aims to publicly recognize companies that prioritize employee health management from a managerial perspective and actively implement initiatives to enhance employee well-being.

Since 2010, we have continuously pursued “kaizen” improvement activities. Over the past decade, our “multi-skilled workforce” has evolved, enabling employees to handle multiple processes and support each other daily. This progress has not only ensured smooth production but also led to a significant reduction in overtime work, contributing to our recognition and certification.

We remain committed to valuing the health and safety of every employee as a crucial asset in our mission to manufacture products that satisfy our customers.

We provide products, environment, and services that enable customers to choose furniture that they like and can use with peace of mind.

We require all our supplier to be traceable and disclosed for all materials used for our product in order to ensure product safety. We also use our own testing equipment to test the strength and durability of our products to ensure safety.

We require all our supplier to be traceable and disclosed for all materials used for our product in order to ensure product safety. We also use our own testing equipment to test the strength and durability of our products to ensure safety.

Including 6 showrooms, 9 sales offices, and online sessions, we cover the whole nation, listen to customers’ concerns, and help them choose products according to their needs.

Including 6 showrooms, 9 sales offices, and online sessions, we cover the whole nation, listen to customers’ concerns, and help them choose products according to their needs.

Please leave the after-sales service such as repair and maintenance of furniture that have been used for a long time.

Please leave the after-sales service such as repair and maintenance of furniture that have been used for a long time.

Fuji Furniture has obtained JISQ 9001: 2015, an international standard for quality management systems established by the International Organization for Standardization, at our head office, factory, and all sales offices, and JISQ 14001: 2015, an international standard for environmental management systems, at our head office and factory.

Communicating Tokushima’s history, culture, and charm through internships and activities with Tokushima City outsiders.Population growth and employment expansion in Tokushima (Not only in Japan, but also in Europe, America and Asian countries).

We take internships for college students. In order to increase the motivation of students to work, we provide opportunities for them to experience working in various workplaces.

We take internships for college students. In order to increase the motivation of students to work, we provide opportunities for them to experience working in various workplaces.

We welcome local elementary school students on factory tours. We provide a place to visit various sites.

We welcome local elementary school students on factory tours. We provide a place to visit various sites.

At the request of our local schools, we deliver on-site lessons—educational programs where our company visits schools to help children understand how their daily learning and experiences connect to society

Our journey has been marked by continually challenging ourselves with each changing era. While these challenges often brought the pain of “failure”, they also led to new discoveries and achievements through “creative destruction.” These experiences enable us to effectively convey to children the importance of embracing challenges without fear of failure.

At the request of our local schools, we deliver on-site lessons—educational programs where our company visits schools to help children understand how their daily learning and experiences connect to society

Our journey has been marked by continually challenging ourselves with each changing era. While these challenges often brought the pain of “failure”, they also led to new discoveries and achievements through “creative destruction.” These experiences enable us to effectively convey to children the importance of embracing challenges without fear of failure.

We promote the sorting, classification and recycling of waste.

In addition, we are working to reduce CO2 emissions and preserve the beautiful environment of Tokushima for children in the future by burning scraps in boilers and effectively using the heat generated in the drying rooms to reduce power consumption.

We promote the sorting, classification and recycling of waste.

In addition, we are working to reduce CO2 emissions and preserve the beautiful environment of Tokushima for children in the future by burning scraps in boilers and effectively using the heat generated in the drying rooms to reduce power consumption.

In order to increase understanding and interest in Tokushima culture, we are carrying out activities to convey to the world through exhibitions and individual exhibitions of the JAPAN brand called “Karakuri.”

In order to increase understanding and interest in Tokushima culture, we are carrying out activities to convey to the world through exhibitions and individual exhibitions of the JAPAN brand called “Karakuri.”

The Head Office invites people to donate blood several times a year.

The Head Office invites people to donate blood several times a year.

Our greenhouse gas reduction targets have been certified by the global initiative “Science Based Targets (SBT) for small and medium-sized enterprises (SMEs).” An SBT is a greenhouse gas emissions reduction target aligned with the levels set by the Paris Agreement. The SBT for SMEs aims to curb global temperature rise to well-below 2°C above pre-industrial levels by 2030, focusing on reducing Scope 1 (direct greenhouse gas emissions from our operations) and Scope 2 (indirect greenhouse gas emissions from the use of purchased electricity or other energy products) emissions.

We will continue to monitor and reduce greenhouse gas emissions in our business activities, striving to build a sustainable society.

Our greenhouse gas reduction targets have been certified by the global initiative “Science Based Targets (SBT) for small and medium-sized enterprises (SMEs).” An SBT is a greenhouse gas emissions reduction target aligned with the levels set by the Paris Agreement. The SBT for SMEs aims to curb global temperature rise to well-below 2°C above pre-industrial levels by 2030, focusing on reducing Scope 1 (direct greenhouse gas emissions from our operations) and Scope 2 (indirect greenhouse gas emissions from the use of purchased electricity or other energy products) emissions.

We will continue to monitor and reduce greenhouse gas emissions in our business activities, striving to build a sustainable society.

We have obtained certification from the Minister of Economy, Trade and Industry for our preemptive disaster prevention and mitigation plan. This initiative aims to ensure the safety of everyone involved with FUJI FURNITURE, secure community safety, and minimize damage to critical resources in the event of major natural disasters such as earthquakes, thereby strengthening our business continuity.

As a member of the local community, we will continue to build a disaster-resilient organization and contribute to sustainable social development.

We have obtained certification from the Minister of Economy, Trade and Industry for our preemptive disaster prevention and mitigation plan. This initiative aims to ensure the safety of everyone involved with FUJI FURNITURE, secure community safety, and minimize damage to critical resources in the event of major natural disasters such as earthquakes, thereby strengthening our business continuity.

As a member of the local community, we will continue to build a disaster-resilient organization and contribute to sustainable social development.

Since 2010, we have significantly reduced product and work-in-process inventories through kaizen activities and environmental improvements. Our goal is to further reduce inventory levels 50% by 2030.

To achieve this ambitious goal, we will do two things

(1) We will review our production methods and product lines to improve production efficiency and quality, and build a more complete cell line system.

(2) We will evolve into a company that is easy to work for, regardless of age or gender, by reducing the physical burden of the work environment so that employees can perform at a high level for longer periods of time.

Since 2010, we have significantly reduced product and work-in-process inventories through kaizen activities and environmental improvements. Our goal is to further reduce inventory levels 50% by 2030.

To achieve this ambitious goal, we will do two things

(1) We will review our production methods and product lines to improve production efficiency and quality, and build a more complete cell line system.

(2) We will evolve into a company that is easy to work for, regardless of age or gender, by reducing the physical burden of the work environment so that employees can perform at a high level for longer periods of time.

We use thinned Japanese Mizunara oak timber from Hokkaido, Japan to make our products.

Thinned timber refers to the timber generated during forest thinning, a process which involves the removal of select standing timber in order to reduce forest density.

Thinning is forestry activity indispensible for coexistence with forests which promotes the healthy growth of timber.

The thinned small-diameter timber material, although small in size, is still beautiful Japanese oak. It takes a lot of time and effort to make a product from this kind of wood, however we are committed to creating products that make the most of the beauty of Japanese Mizunara oak.

We use thinned Japanese Mizunara oak timber from Hokkaido, Japan to make our products.

Thinned timber refers to the timber generated during forest thinning, a process which involves the removal of select standing timber in order to reduce forest density.

Thinning is forestry activity indispensible for coexistence with forests which promotes the healthy growth of timber.

The thinned small-diameter timber material, although small in size, is still beautiful Japanese oak. It takes a lot of time and effort to make a product from this kind of wood, however we are committed to creating products that make the most of the beauty of Japanese Mizunara oak.

Cutting scraps, polishing powder, and other manufacturing residuals are collected and incinerated in a wood waste boiler. The thermal energy generated during incineration is then used as a heat source for the drying room where coated products are dried. This process ensures that resources are utilized effectively rather than simply being burned away.

Thermal recycling of waste, or using waste as an energy resource, contributes to achieving the Sustainable Development Goals (SDGs) “11. Make cities and human settlements inclusive, safe, resilient, and sustainable” and “12. Ensure sustainable consumption and production patterns.”

Cutting scraps, polishing powder, and other manufacturing residuals are collected and incinerated in a wood waste boiler. The thermal energy generated during incineration is then used as a heat source for the drying room where coated products are dried. This process ensures that resources are utilized effectively rather than simply being burned away.

Thermal recycling of waste, or using waste as an energy resource, contributes to achieving the Sustainable Development Goals (SDGs) “11. Make cities and human settlements inclusive, safe, resilient, and sustainable” and “12. Ensure sustainable consumption and production patterns.”

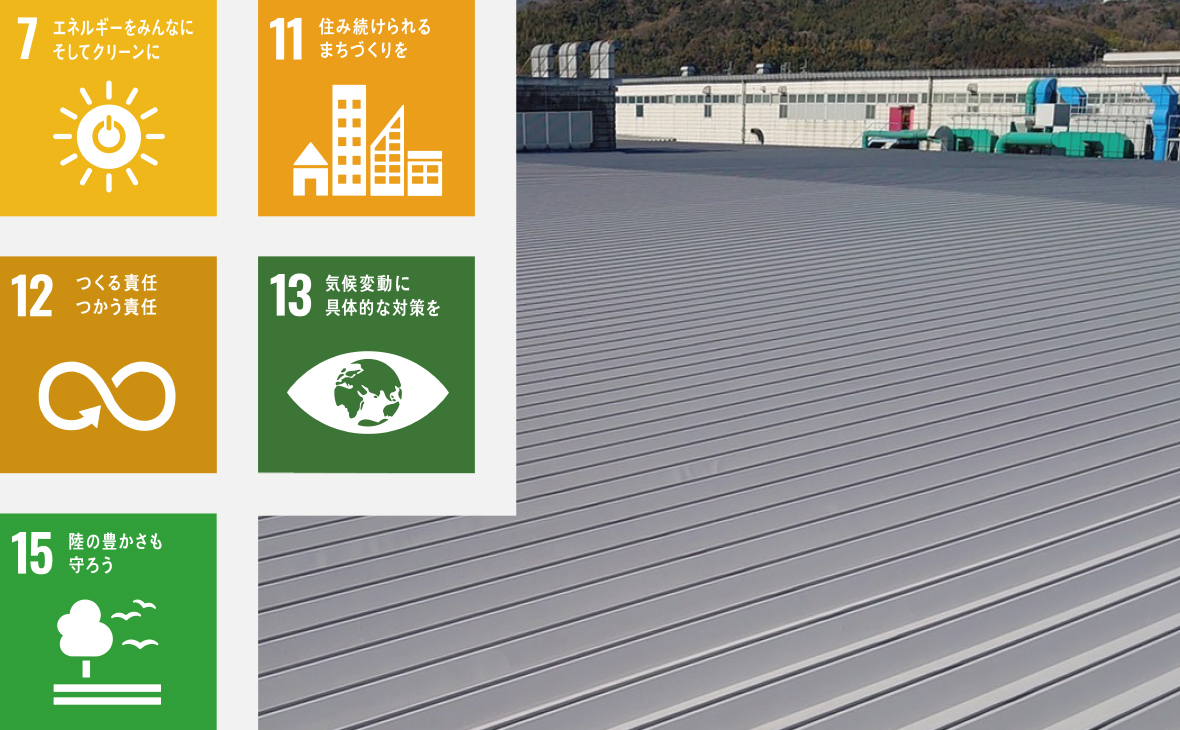

The roofs of our factories are coated with a thermal barrier that helps regulate indoor temperatures. This coating reduces temperature rises by 3 to 4°C in summer and limits temperature drops by 3 to 4°C in winter. As a result, it decreases the need for air-conditioning, thus reducing electricity consumption.

The implementation of thermal barrier coated roofs aligns with several Sustainable Development Goals (SDGs), including:

“7. Ensure access to affordable, reliable, sustainable and modern energy for all,”

“11. Make cities and human settlements inclusive, safe, resilient, and sustainable,”

“12. Ensure sustainable consumption and production patterns.”,

“13. Take urgent action to combat climate change and its impacts”,

and “15. Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss.”

The roofs of our factories are coated with a thermal barrier that helps regulate indoor temperatures. This coating reduces temperature rises by 3 to 4°C in summer and limits temperature drops by 3 to 4°C in winter. As a result, it decreases the need for air-conditioning, thus reducing electricity consumption.

The implementation of thermal barrier coated roofs aligns with several Sustainable Development Goals (SDGs), including:

“7. Ensure access to affordable, reliable, sustainable and modern energy for all,”

“11. Make cities and human settlements inclusive, safe, resilient, and sustainable,”

“12. Ensure sustainable consumption and production patterns.”,

“13. Take urgent action to combat climate change and its impacts”,

and “15. Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss.”